Maidecal

Machinery

Professional manufacturer of plastic auxiliary equipment.

We engineer intelligent, high-efficiency solutions for the global plastic industry.

WHO WE ARE

Integrated Solutions for Plastic Processing

Jiangsu Maidecal Seiko Technology Co., Ltd. combines R&D, manufacturing, and global sales. We don't just build machines; we optimize your entire production line with rigorous quality control and energy-saving designs.

FEATURED SERIES

HKS Low Speed

Mute Granulator

Engineered for machine-side instant recycling. The HKS series eliminates the chaos of traditional crushing. Its unique rack cutter design and low-speed operation ensure a dust-free, ultra-quiet environment.

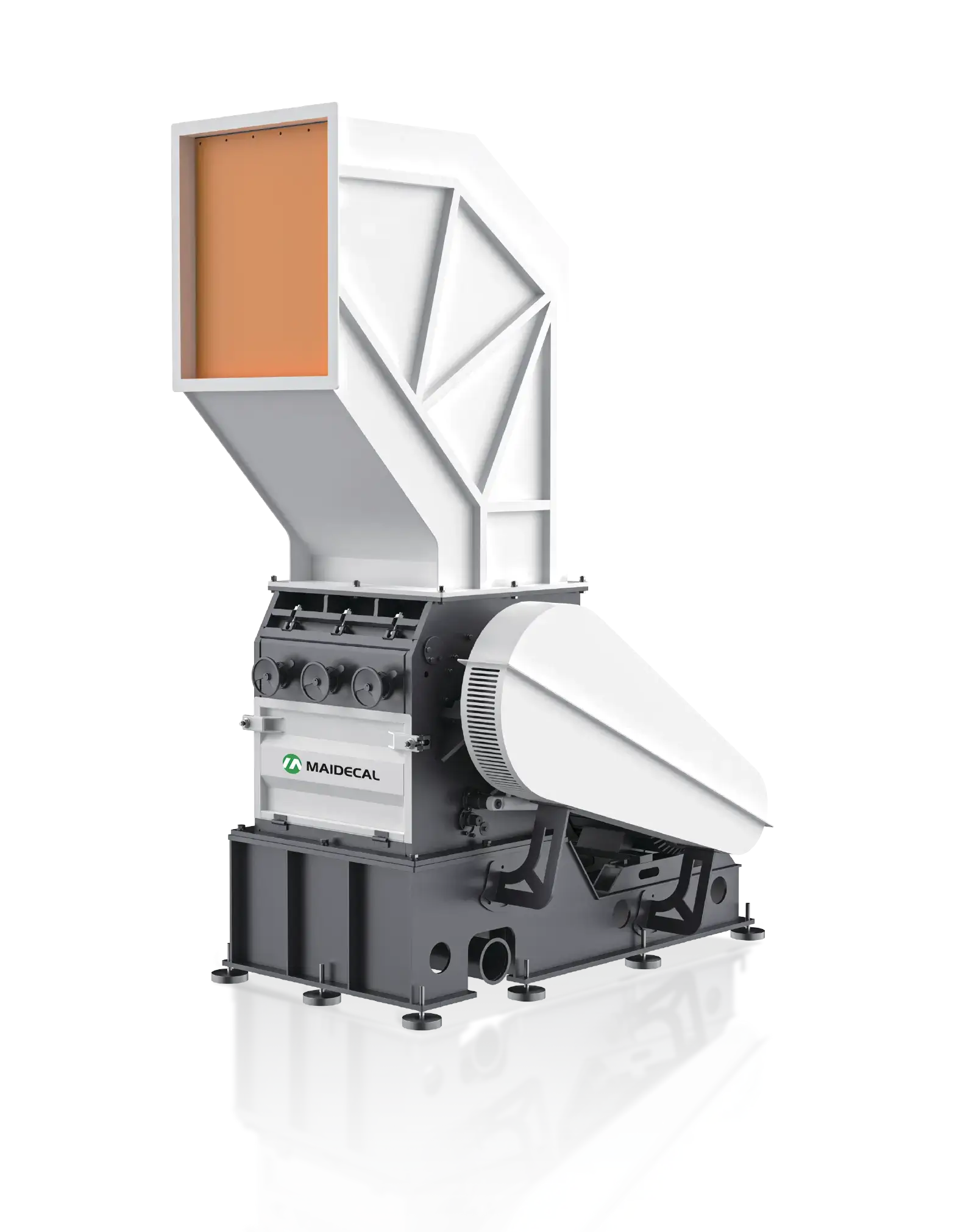

HEAVY DUTY LINE

HDC Series

Central Crusher

Uncompromising power for tough materials. Featuring a V-shaped rotor design and external bearing housing, the HDC series effortlessly processes large plastic parts, thick pipes, sheets, and profiles with high throughput.

COMPLETE ECOSYSTEM

Auxiliary Equipment

Everything you need to optimize your plastic production line, from temperature control to material handling.

High-efficiency shell and tube condensers. Precise temp control (3-5°C) for stable molding.

Compact and efficient cooling without the need for a water tower. Ideal for flexible placement.

Umbrella-type dispersion ensures uniform blending in minutes. Optional heating available.

Advanced PID control for precise mold heating. Available in Water and Oil types.

Stainless steel construction with shortage alarms. Automate feeding and reduce labor.

Curved hot air design ensures uniform drying of raw materials, preventing moisture defects.

Need a Custom Solution?

Our engineers can assess your factory layout and material requirements to build a tailored auxiliary system.

Contact Engineering TeamReady to Increase Efficiency?

Get a competitive quote with global shipping options today.

Get a Free Quote Now