Introduction to Heavy-Duty Industrial Cutter Blades

Heavy-duty industrial cutter blades play a critical role in various industries, serving as vital tools designed to tackle tough materials with precision. These blades are tailored to endure the rigors of demanding applications, setting themselves apart from standard cutter blades through their superior material composition and specialized design features. Typically crafted from high-grade steel or carbide, heavy-duty blades exhibit enhanced durability, allowing them to maintain sharpness and structural integrity under high-stress conditions.

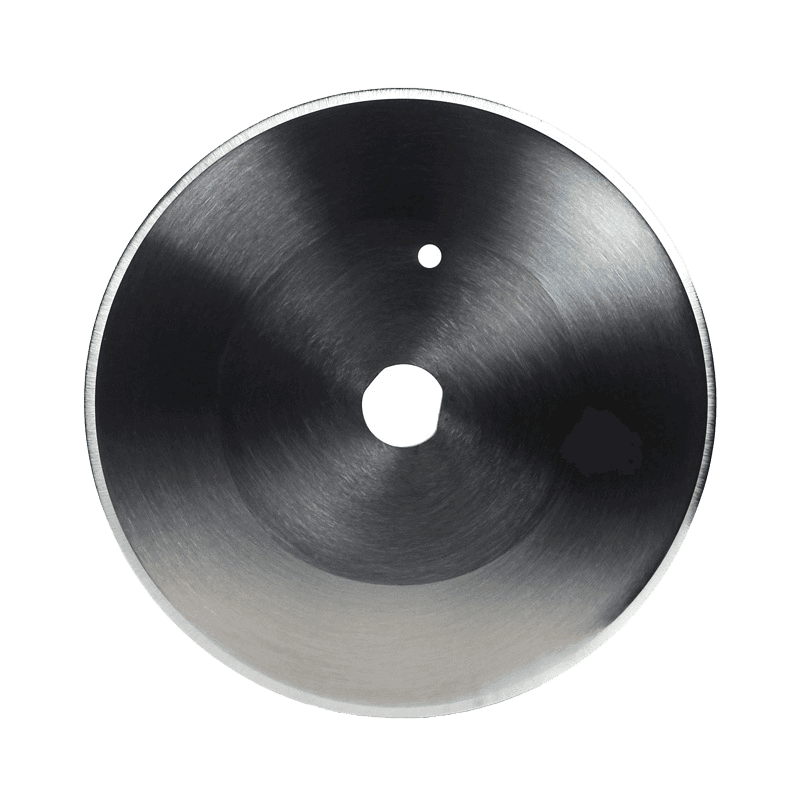

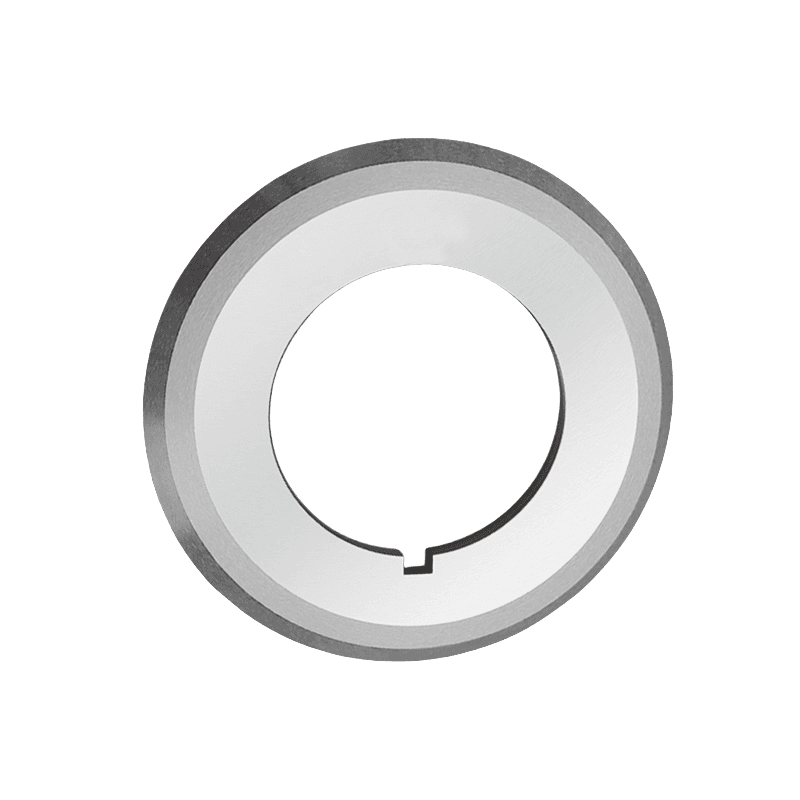

The design of heavy-duty industrial cutter blades often includes specific attributes such as thicker cutting edges, reinforced tips, and optimized geometry, which facilitate efficient slicing, cutting, or trimming of materials ranging from metals and plastics to heavy textiles. These blades are engineered to withstand higher levels of wear and tear, thereby reducing the frequency of replacements and contributing to lower operational costs over time. In various sectors, including metalworking, plastics manufacturing, and construction, the longevity and reliability of heavy-duty cutter blades are paramount to effective productivity.

Investing in high-quality heavy-duty industrial cutter blades is essential for businesses aiming to enhance workflow efficiency. The enhanced performance characteristics of these blades ensure that they can consistently deliver accurate cuts and reduce downtime associated with blade failures. This not only streamlines production processes but also improves overall safety, as blades that perform reliably lower the risk of accidents caused by equipment malfunction. As industries continue to evolve, the demand for durable and efficient cutting tools remains crucial, underlining theimportance of heavy-duty industrial cutter blades as a cornerstone in any robust production environment.

Benefits of Upgrading to Heavy-Duty Cutter Blades

Upgrading to heavy-duty industrial cutter blades offers numerous advantages for businesses across various sectors. One primary benefit is enhanced cutting efficiency. Heavy-duty cutter blades are designed to handle demanding tasks, cutting through tougher materials with precision and speed. This efficiency translates into reduced operational time, allowing businesses to increase productivity. For instance, a manufacturing company reported a 30% reduction in cutting time after switching to heavy-duty blades, showcasing a significant improvement that can directly impact the bottom line.

Another vital aspect is the reduction in downtime. Conventional cutter blades can wear out quickly, leading to frequent replacements and operational interruptions. By investing in high-quality heavy-duty blades, businesses can experience longer-lasting performance, minimizing the need for frequent blade changes. Companies that upgraded noted a decrease in unscheduled maintenance, enabling them to allocate their resources more efficiently and focus on production rather than repairs.

Safety is also a crucial factor. Many heavy-duty industrial cutter blades come with enhanced safety features, such as advanced locking mechanisms and better blade retention systems, reducing the risk of accidents in the workplace. This improvement creates a safer environment for employees, fostering a culture of safety that can reduce liability and enhance employee morale.

Furthermore, while the initial investment in heavy-duty cutter blades may be higher, the long-term cost-effectiveness is evident. By decreasing maintenance costs and increasing productivity, businesses often find that these blades provide a solid return on investment over time. For example, a packaging company found that by using heavy-duty blades, they not only reduced waste but also improved the quality of their finished products, leading to greater customer satisfaction and repeat business.

In conclusion, the transition to heavy-duty industrial cutter blades not only enhances operational efficiency but also contributes to safer work environments and long-term savings. By adopting these advanced tools, businesses can significantly improve both their processes and outputs.

Selecting the Right Heavy-Duty Cutter Blades for Your Needs

Choosing the appropriate heavy-duty industrial cutter blades for your specific applications involves a thorough assessment of various factors that influence cutting performance and efficiency. One of the primary considerations is the size of the blades. Industrial applications may require blades of varying lengths and widths, contingent on the materials being cut and the precision required for the job. For example, larger blades are often better suited for heavy materials, while smaller blades may offer greater control in detailed cutting tasks.

The material composition of the blades also plays a critical role in their effectiveness. Heavy-duty cutter blades are available in a range of materials, including high-speed steel (HSS), carbide-tipped, and diamond-coated options. Each material has its unique properties, such as hardness and wear resistance, making some more suitable for specific applications than others. Depending on the nature of the materials being processed—be it wood, metal, plastic, or composites—selecting the correct material can significantly enhance productivity and reduce the frequency of blade replacements.

Furthermore, the cutting edge angle is an essential consideration. Different angles can influence the efficiency of the cut and the quality of the finished product. A sharp, acute angle is typically ideal for smooth cuts, while a more obtuse angle may be better for durability in challenging applications.

Compatibility with existing machinery is another critical factor to consider when selecting heavy-duty cutter blades. Ensuring that the blades fit well with your current equipment not only promotes safety but also maximizes performance. It is advisable to consult machinery specifications and manufacturer recommendations when making your choice.

Finally, assessing your business’s cutting needs can be instrumental in determining the optimal blades. Take into account daily usage, material types, and production volumes. Engaging in discussions with suppliers can ensure you negotiate favorable contracts that deliver both quality assurance and cost efficiency, ultimately supporting your business’s operational goals.

Maintenance and Care for Long-Lasting Performance

Maintaining heavy-duty industrial cutter blades is crucial to ensure their longevity and optimal performance. Regular care not only enhances their efficiency but also extends their operational life, ultimately saving costs and downtime for your business. Implementing a routine maintenance schedule is the first step in this process. A systematic approach can significantly prevent unexpected blade failures and performance drops.

Routine checks should be conducted to inspect the blades for any signs of wear or damage. Look out for chips, cracks, or dullness in the cutting edges. If any issues are identified, they should be addressed immediately, either by sharpening the blades or replacing them altogether. Regularly checking the blades can help catch potential problems early, preventing more significant and costly repairs in the future.

Cleaning is another essential aspect of blade maintenance. After each use, remove debris, dust, or residue that may accumulate on the blades. Using a soft brush or cloth, gently wipe down the surfaces to maintain their integrity. This practice not only keeps the blades working efficiently but also prevents corrosion, which can diminish their effectiveness over time.

Sharpening techniques are critical to ensuring that heavy-duty industrial cutter blades remain effective. It is advisable to follow the manufacturer’s recommendations for sharpening frequency and methods. Utilizing the appropriate sharpening tools—whether they be honing stones, grinders, or specialized sharpeners—is essential to maintain the precise edge required for cutting performance.

Finally, proper storage of the blades is vital for preventing damage. Keeping blades in protective cases or designated racks can shield them from external elements and physical harm. By investing in the maintenance and care protocols for heavy-duty industrial cutter blades, businesses can ensure consistent workflow, minimize replacement costs, and enhance overall operational efficiency.