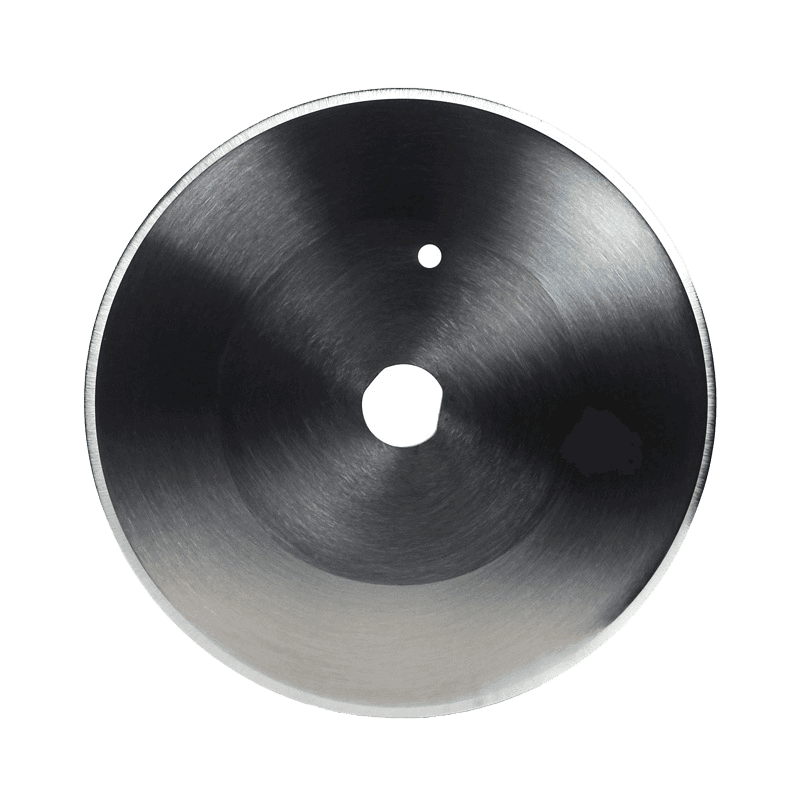

Introduction to Carbide Cutting Tools

Carbide cutting tools are essential instruments in various industries, particularly those requiring precision machining and engineering. These tools are crafted primarily from cemented carbide, a composite material that combines hard metal carbides, such as tungsten carbide, with a binder metal, often cobalt. The manufacturing process involves sintering, where the powder components are subjected to high temperatures and pressure, resulting in a solid, dense material. This process not only enhances the hardness of the tools but also increases their durability, making them ideal for demanding applications.

The unique properties of cemented carbide contribute significantly to its prevalent use in cutting tools. One of its most notable characteristics is its exceptional hardness, which allows cutting tools to maintain sharp edges even after extended use. This property is vital for precision work, as it ensures that the tools can cut through various materials—ranging from steel to softer alloys—while maintaining accuracy and quality in the finished product. Additionally, carbide cutting tools exhibit remarkable wear resistance. This characteristic minimizes the need for frequent replacements, thus reducing downtime in manufacturing processes.

Furthermore, the thermal stability of cemented carbide tools is excellent. They can withstand high temperatures generated during machining operations without losing their structural integrity, which is crucial for the consistency of high-quality results. The combination of hardness, wear resistance, and thermal stability makes carbide cutting tools an optimal choice for professionals in fields such as automotive, aerospace, and manufacturing, where precision is paramount to achieving desired outcomes. Ultimately, understanding these foundational properties will elucidate the numerous benefits of employing carbide cutting tools in precision work.

Enhanced Precision in Machining

Cemented carbide cutting tools play a critical role in achieving enhanced precision during machining processes. Known for their exceptional hardness and wear resistance, these tools enable manufacturers to perform intricate cuts with remarkable accuracy. The unique composition of cemented carbide, which typically consists of tungsten carbide particles bonded with a metallic binder, provides the ideal characteristics for maintaining sharpness and integrity even under demanding conditions. As a result, industries can benefit from tighter tolerances and superior surface finishes.

The ability of cemented carbide to withstand high temperatures and retain its cutting edge allows for consistent performance throughout the machining process. Traditional cutting tools often struggle with wear and thermal degradation, leading to inaccuracies in dimension and finish. However, carbide tools minimize these shortcomings, ensuring that precision parts can be produced with less frequency of tool replacements and reduced machining time. This advantage is particularly valuable in high-volume production settings where maintaining tight tolerances is crucial.

Various industries benefit significantly from utilizing carbide cutting tools for precision work. The aerospace sector, for example, relies on the ability to produce components with stringent dimensional specifications and surface quality. Similarly, the automotive industry often employs these tools for manufacturing engine parts that demand high precision to ensure optimal performance and durability. Additionally, advanced manufacturing sectors, including medical device production, also rely on cemented carbide for creating intricate, high-quality components. This versatility illustrates the importance of carbide cutting tools in modern machining applications, as they facilitate improved accuracy and efficiency across a variety of fields.

Increased Durability and Longevity

Cemented carbide cutting tools are renowned for their exceptional durability and longevity, making them a superior choice in precision work compared to traditional cutting tools. Composed primarily of tungsten carbide, these tools are engineered to withstand the harsh conditions often encountered in machining operations. The inherent properties of cemented carbide, such as its high hardness and strong resistance to wear, result in a remarkable capability to maintain their cutting edges for extended periods.

Wear resistance is a critical factor when assessing cutting tool longevity, and cemented carbide excels in this area. Unlike conventional materials, which can degrade quickly under prolonged stress, carbide maintains its structural integrity, allowing it to perform effectively over time. This resistance to wear minimizes the frequency of tool replacements, which is not only economically beneficial but also enhances overall productivity. Consequently, manufacturers can experience significant cost savings linked to the reduced need for purchasing new tools.

Chipping and breakage are common issues faced with traditional cutting tools; however, cemented carbide demonstrates superior toughness that mitigates these problems. The combination of hardness and resilience inherent in carbide materials enables them to resist chipping under impact and stress. As a result, manufacturers can undertake demanding machining tasks with confidence, knowing that they are utilizing tools designed to perform reliably in an array of applications.

In summary, the durability and longevity offered by cemented carbide cutting tools represent a significant advantage for manufacturers seeking optimal performance and cost-effectiveness. By choosing carbide tools, companies can ensure greater productivity, lower operational costs, and enhanced output quality, making them an excellent investment for any precision work. This focus on durability ultimately leads to diminished downtime and maximized efficiency in the production process.

Higher Efficiency and Productivity

The use of carbide cutting tools, particularly those made from cemented carbide, has garnered significant attention in the machining industry due to their superior efficiency and productivity enhancements. One of the most notable advantages of cemented carbide tools is their ability to maintain a consistently sharp cutting edge over prolonged usage periods. This characteristic allows for faster cutting speeds compared to conventional tooling materials, thereby minimizing the time required to complete machining tasks.

When tools retain their sharpness, they facilitate smoother and faster cuts, which directly translates into reduced cycle times. Operators can achieve high-quality finishes without frequently stopping for tool changes or maintenance, optimizing workflow and decreasing machine downtime. Essentially, this seamless operation contributes to higher output rates, making cemented carbide a preferred choice in high-volume manufacturing contexts where time efficiency is a critical factor.

Additionally, the inherent durability of carbide cutting tools means that they are less prone to wear and tear. This durability allows for longer periods between tool replacements, reducing overall costs associated with tooling management and procurement. In environments where precision is paramount, such as aerospace or automotive industries, the reliability of cemented carbide tools ensures that production specifications are met consistently, further supporting productive output.

Moreover, the reduced friction and heat generation associated with cemented carbide cutting tools allow for an improved machining environment. Lower operational temperatures can lead to increased tool life and further optimize machining parameters for efficiency. Overall, the use of carbide cutting tools enables businesses to maximize productivity while maintaining high standards of precision, establishing these tools as essential components in modern machining strategies.

Versatility Across Materials

Cemented carbide cutting tools are renowned for their exceptional versatility, making them indispensable in various industrial applications. One of the primary advantages of these tools is their ability to effectively machine a wide range of materials, including metals, plastics, and composites. This adaptability facilitates the seamless switch between different machining processes without the need for extensive tool changes, thereby enhancing operational efficiency.

When working with metals, carbide tools excel in delivering precision cuts and maintaining sharp edges, even under high temperatures and abrasive conditions. Their hardness and wear resistance allow them to perform well with various alloys, from soft metals such as aluminum to harder materials like stainless steel and titanium. This broad capability enables manufacturers to utilize carbide cutting tools across diverse fabrication processes, thus streamlining production workflows.

In addition to metals, carbide cutting tools are equally effective when machining plastics. The low friction properties of cemented carbide minimize the risk of thermal deformation during the cutting process, ensuring a clean and precise finish. This quality is particularly beneficial in applications involving intricate designs in various plastic materials, as it helps to avoid melting or warping that can occur with less effective tool materials.

Furthermore, the versatility of carbide tools extends to composite materials, which are increasingly common in sectors such as aerospace and automotive. These materials often possess unique challenges due to their layered structure and varying densities. Cemented carbide cutting tools can be employed to machine composites without delaminating or damaging the material, affirming their status as a reliable choice in industries that handle complex materials.

In conclusion, the versatility of cemented carbide cutting tools positions them as a superior option for businesses engaged in precision work across a multitude of materials. Their capacity to adapt to various machining processes ensures optimal performance and quality results, essential for today’s dynamic manufacturing environments.

Cost-Effectiveness in the Long Run

When considering tools for precision work, the initial investment is often a major factor in the decision-making process. However, when evaluating the overall cost-effectiveness of using carbide cutting tools, it becomes clear that the immediate costs can be outweighed by significant long-term savings. Cemented carbide tools, known for their outstanding hardness and wear resistance, provide notable longevity compared to their high-speed steel or other conventional counterparts.

One of the primary advantages of investing in cemented carbide tools is their extended lifespan. Unlike standard cutting tools that may require frequent replacements, carbide cutting tools can endure longer operational periods without degrading in performance. This durability translates directly into cost savings, as businesses will experience lower expenditure on tool replacements over time. Moreover, while the upfront costs of carbide tools may be higher, their ability to maintain sharpness and resist wear means that they require less frequent replacement.

Additionally, the efficiency gained from using carbide cutting tools can contribute to reduced production costs. These tools facilitate faster machining times and superior finishes, enabling manufacturers to enhance overall productivity. This efficiency not only results in quicker turnaround times but also decreases the need for subsequent finishing processes, further aiding in cost reduction.

Maintenance is another area where carbide cutting tools shine. Their robust nature typically requires less frequent maintenance compared to softer materials. As a result, companies can allocate fewer resources towards tool upkeep, allowing for better allocation of budget and labor.

In conclusion, utilizing carbide cutting tools can provide substantial cost benefits in the long run. By investing in these durable tools, businesses can achieve lower total ownership costs, making them a financially sound option for precision work.

Environmental Impact and Sustainability

In recent years, there has been a growing focus on the environmental impact of manufacturing processes and the need for sustainability. The use of carbide cutting tools has emerged as a beneficial solution in this regard, thanks to their durability and efficiency. Cemented carbide tools are designed to last significantly longer than traditional cutting tools, resulting in less waste generation over time. The increased lifespan of these tools means that fewer raw materials are required for production, which ultimately reduces the overall environmental footprint associated with tool manufacturing.

Moreover, carbide cutting tools contribute to sustainability by minimizing the energy consumption during machining. Due to their inherent strength and resistance to wear, these tools can operate at higher speeds and feeds. This efficiency not only enhances productivity but also lowers the amount of energy needed to perform the cutting operations. The combination of reduced energy usage and waste generation aligns well with the manufacturing industry’s ongoing transition towards environmentally responsible practices.

Additionally, the long service life of cemented carbide tools facilitates a decrease in the frequency of tool replacement. This characteristic allows manufacturers to implement more effective waste management strategies, as less frequent disposal of worn tools results in diminished environmental impact. As industries seek to adopt more sustainable solutions, carbide cutting tools provide a compelling option, contributing positively to both operational effectiveness and environmental responsibility.

Overall, the integration of carbide tools into manufacturing processes supports sustainability initiatives while also ensuring precision and high-quality output. By emphasizing efficient resource usage, companies can achieve a balance between operational needs and environmental stewardship. The ongoing commitment to sustainability in manufacturing underscores the importance of selecting tools that not only enhance productivity but also align with broader environmental goals.

Choosing the Right Carbide Cutting Tools

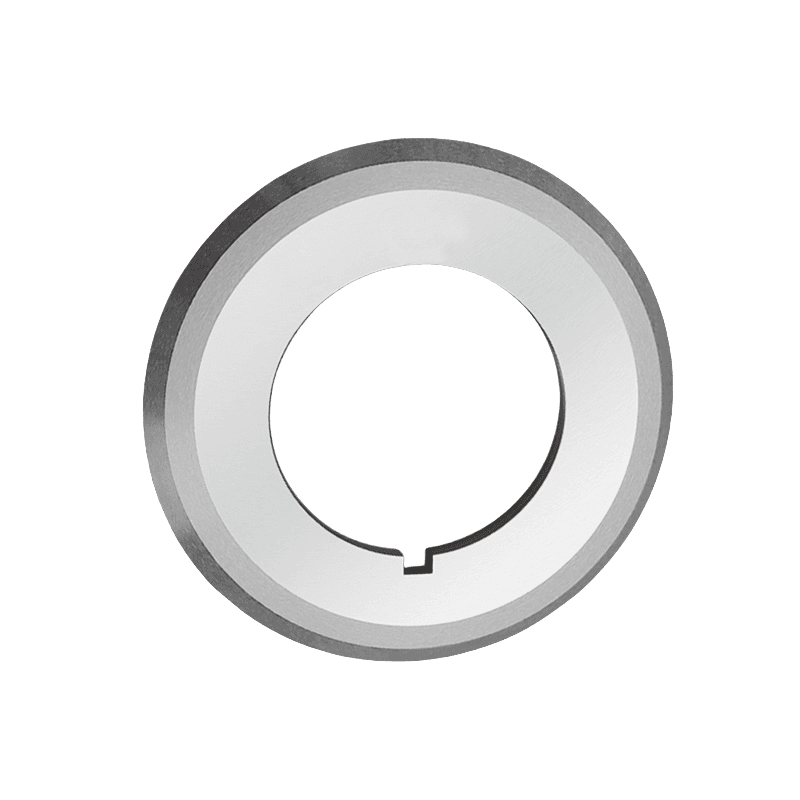

Selecting the appropriate carbide cutting tools for specific applications is crucial for achieving optimal results in precision work. The first step in this process involves identifying the types of materials that will be machined. Different carbide grades and properties are designed for varying materials, such as steel, aluminum, or composites. Each material demands a certain level of hardness and wear resistance in the cutting tool to ensure efficiency and longevity.

Another factor to consider is the level of precision required for your work. Carbide cutting tools offer various shapes, sizes, and configurations, each tailored to specific cutting operations. For instance, end mills, drills, and inserts have different geometries that influence cutting performance. A thorough understanding of your machining requirements will aid in selecting the right tool for the job. Higher precision applications may benefit from specialized carbide cutting tools designed for minimal tolerances and intricate cuts, whereas general applications might only require standard configurations.

Performance requirements also play a significant role in this selection process. Evaluating the expected cutting speeds, feed rates, and overall machining conditions will guide the choice of carbide tools. Some carbide cutting tools are optimized for high-speed machining, while others excel in heavy-duty applications. It is advisable to analyze product specifications provided by manufacturers to ensure that the tools can meet your operational demands and environmental conditions.

Furthermore, finding reputable manufacturers is essential in guaranteeing that you receive high-quality carbide cutting tools. Look for suppliers known for their rigorous quality control processes and customer service. Reading reviews and consulting industry professionals can also provide insights into reliable manufacturers. By taking these factors into account, you can confidently select the best carbide cutting tools for your precision work, leading to improved productivity and outcomes.

Conclusion and Final Thoughts

In conclusion, the numerous benefits of using carbide cutting tools, particularly those made from cemented carbide, can transform machining processes significantly. These tools are revered for their impressive durability, allowing them to withstand the rigors of high-speed machining and hard material cutting. The robustness of cemented carbide results in a prolonged tool life, which ultimately reduces the frequency of replacements and minimizes overall operational costs.

Moreover, carbide cutting tools offer enhanced precision, which is essential in industries that demand stringent tolerances. Their ability to maintain sharp edges, even after prolonged use, enables machinists to achieve a level of accuracy that is hard to match with other materials. This precision contributes not only to improving product quality but also to increasing the efficiency of the manufacturing process, leading to less waste and downtime.

Additionally, the versatility of cemented carbide tools makes them suitable for a wide range of applications, from machining metals to softer materials. The adaptability of these cutting tools allows manufacturers to utilize them across various projects, further emphasizing their value in diverse machining environments.

Investing in carbide cutting tools means investing in the future of a business. The combination of enhanced precision, durability, and overall efficiency will certainly yield long-term advantages that can propel a company ahead of its competitors. As industries continue to evolve and demands increase, incorporating these advanced materials into machining practices may be key to sustaining growth and achieving excellence. Therefore, it is wise for companies to consider integrating carbide cutting tools into their operations to reap these benefits for years to come.