1.Key details to note when operating inserted high-speed steel blades

1. Blade quality

The higher the quality of sharpening the blade is, the longer the service life of the cutting blade will be, and the better the cutting quality will be.

2. The types of materials cut by the blade.

During the cutting process, the rate at which the edge of the inserted high-speed steel blade becomes dull is related to the abrasion resistance of the material being cut. When cutting paper, the rate at which the blade becomes dull is related to the hardness of the paper texture and the ash content. The harder the paper texture and the higher the ash content, the faster the blade becomes dull.

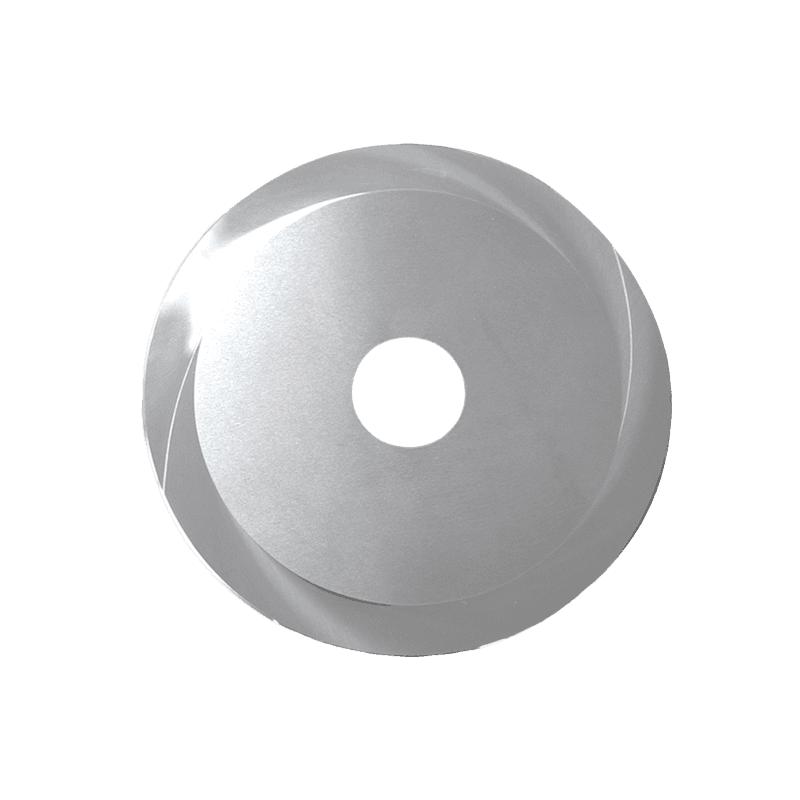

3. Materials for blade knives

The inserted high-speed steel blade is made by high-temperature insert welding of the blade edge and the blade body. The blade edge is made of high-hardness chromium-tungsten-manganese steel, and the blade body is made of low-carbon steel. The durability of the tool is directly proportional to the hardness of the steel used in the blade edge part. For high-quality blades, the hardness of the blade edge part after quenching can reach HR55 – 60.

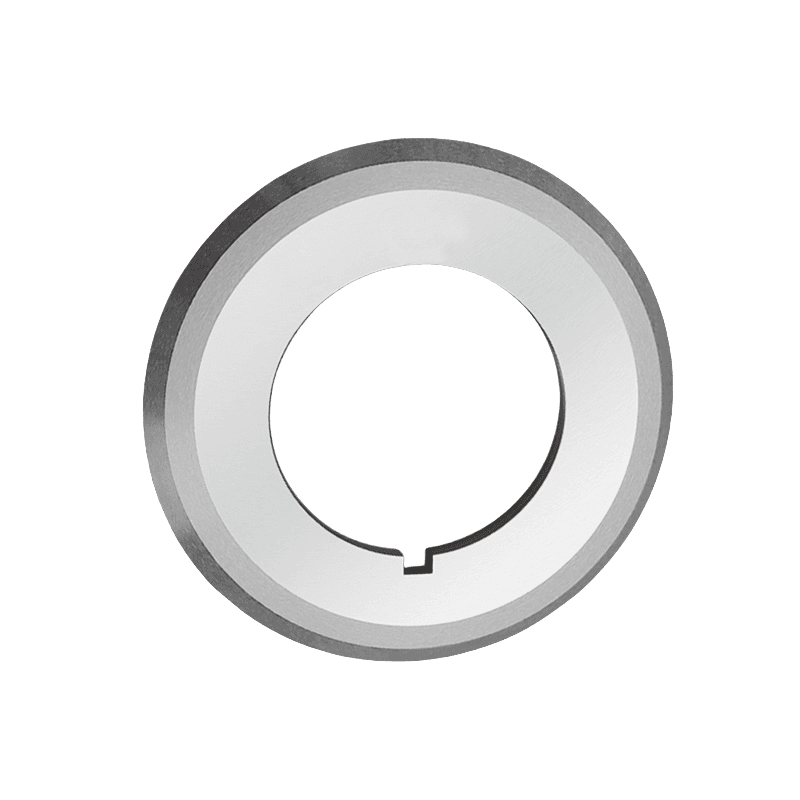

4. Shape and Angle

On a single-sided machine, generally a single-ground-edge tool is used, and the grinding edge angle is between 19° and 23°. However, the grinding edge of this shape makes the bevel surface of the tool bear the pressure from the part of the paper stack that is being cut during the cutting process. Under the friction of the paper edge, the inclined surface of the blade is quickly worn out.

Double-edged knives have significant advantages. Their ground edges help reduce the load on the machine and improve the cutting accuracy. Therefore, when the tool material permits and considering the cutting resistance of the material being cut, the angle of the ground edge should be made as small as possible.

2.Wrong Methods of Polishing Inserted High-speed Steel Blades and Countermeasures

1. Incorrect Angle: Many novices grind the blade perpendicular to the whetstone. This will cause the blade to curl. This method will also create grooves on the whetstone, shortening the lifespan of both the whetstone and the tool.

– Countermeasure: Diagonal Grinding Method. Whether grinding the knife vertically or horizontally, it should be ground along the diagonal. This allows the tool to come into even contact with the whetstone during a back-and-forth grinding process, avoiding blade curling and damage to the whetstone surface.

2. Incorrect Pushing and Pulling: The speed and force of pushing and pulling the knife during sharpening are the same. The freshly sharpened blade is pushed forward with force, causing the blade to become dull.

– Countermeasure: When sharpening the knife, the force should be light when pushing and heavy when pulling. Because pushing forward goes against the blade’s edge, while pulling backward follows the blade’s edge. So, apply more force when pulling, which can sharpen the blade and avoid damage to it. When pushing, the force should be small and the speed slow to prevent blade wear.

3. Incorrect Standing Position: Standing with legs in a straight line makes it impossible to apply all the force to pulling the knife, and it is easy to get tired after long-term knife sharpening.

– Countermeasure: Stand with legs in an “I – shaped” stance. Press the body weight onto the front leg. The body weight will then be transferred to the knife-sharpening process, which is labor-saving and effective.

4. Incorrect Inclination Angle: The angle between the knife and the whetstone is too large. Although this can sharpen the knife relatively quickly, it results in a thicker blade edge on both sides. After a short period of cutting, the blade edge will become dull.

– Countermeasure: The angle between the knife and the whetstone should be kept below 5 degrees. Increase the contact area between the knife and the whetstone to grind the two sides of the blade edge thinner. The thinner the two sides of the blade edge, the sharper the blade, and the better the cutting effect.

5. Incorrect Hand Technique: Holding the blade surface while sharpening the knife makes it impossible to apply an even force. It is easy to cause the blade edges on both sides to be of different thicknesses. Additionally, it is easy to injure your fingers.

– Countermeasure: Use a proper grip on the knife handle to ensure even force application during the sharpening process, which helps to maintain a consistent blade edge thickness and reduces the risk of finger injury.