Introduction

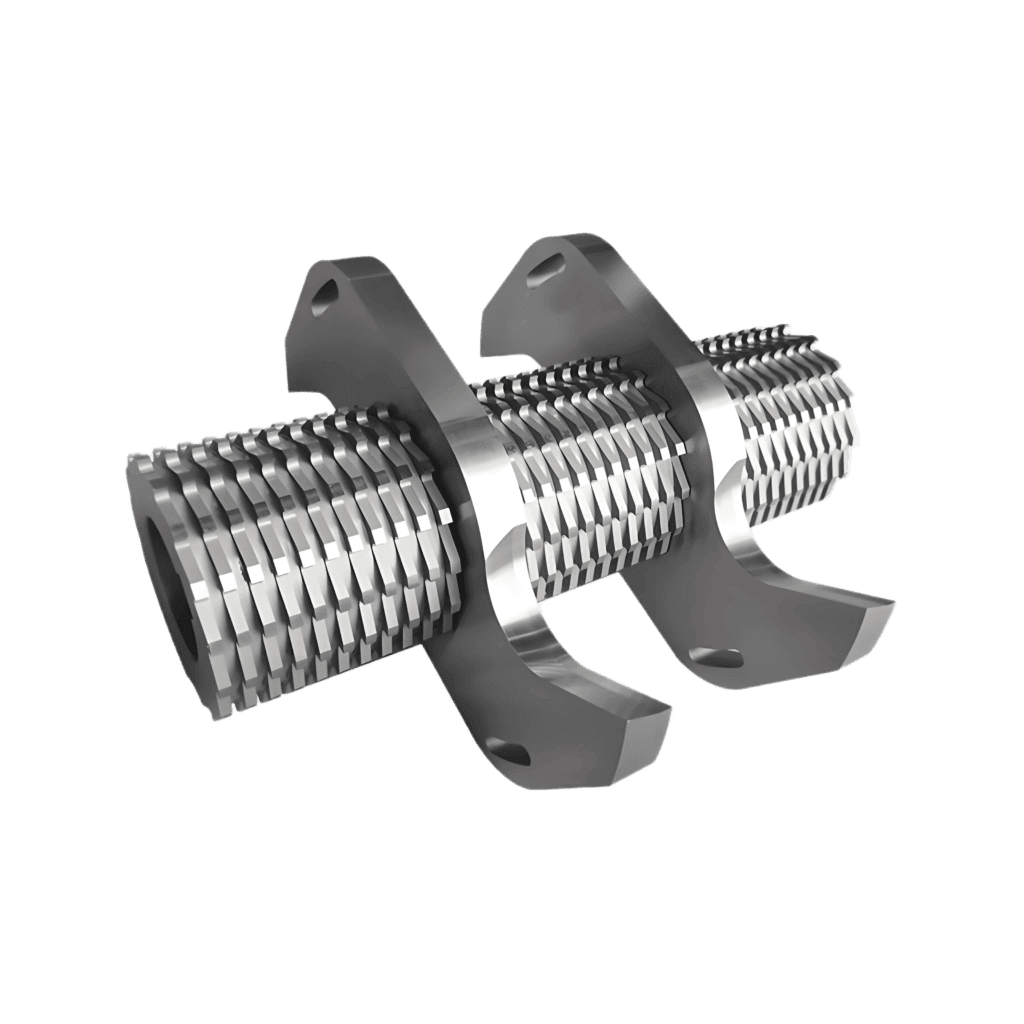

In the realm of industrial recycling, shredder blades play a pivotal role in the efficient processing of materials such as plastics, metals, and wood. Recent technological advancements have significantly enhanced the performance and durability of these blades, leading to improved recycling processes and operational efficiencies.

Technological Innovations in Shredder Blades

The evolution of shredder blades has been marked by several key innovations:

- High-Strength Steel Alloys: Manufacturers are increasingly utilizing high-strength steel alloys to produce shredder blades. These materials offer superior durability and resistance to wear, thereby extending the lifespan of the blades and reducing the frequency of replacements.

- Tungsten Carbide Coatings: Applying Tungsten Carbide coatings to shredder blades enhances their hardness and wear resistance. This advancement is particularly beneficial in processing abrasive materials, as it minimizes blade degradation and maintains cutting efficiency over extended periods.

- Customization for Specific Applications: There is a growing trend towards customizing shredder blades to meet the unique requirements of various recycling processes. Tailored designs ensure optimal performance, whether the goal is to shred plastics, metals, or other materials, thereby improving throughput and reducing downtime.

Impact on Recycling Efficiency

The integration of these technological advancements has led to several notable improvements in recycling efficiency:

- Increased Lifespan of Shredder Blades: The use of advanced materials and coatings has significantly extended the operational life of shredder blades. This longevity translates to fewer replacements and less frequent maintenance interventions.

- Reduction in Maintenance Costs: With enhanced durability, the need for maintenance is reduced, leading to lower operational costs. Companies can allocate resources more effectively, focusing on other critical aspects of their operations.

- Enhanced Processing Speed and Material Throughput: Improved blade performance allows for faster processing of materials, increasing the overall throughput of recycling facilities. This efficiency boost is crucial in meeting the growing demand for recycled materials.

Industry Applications

The advancements in shredder blade technology have had a profound impact across various recycling sectors:

- Plastic Recycling: Enhanced blade durability and customization have improved the shredding of diverse plastic types, facilitating more efficient recycling processes.

- Metal Recycling: The ability to handle tougher materials without compromising precision has been particularly beneficial in metal recycling, where accurate shredding is essential for quality recovery.

- Wood and Paper Recycling: Improved blade performance has streamlined the processing of wood and paper products, contributing to higher-quality recycled outputs.

Market Trends and Growth

The shredder blades market is experiencing significant growth, driven by the increasing demand for efficient recycling solutions:

- Projected Market Growth: The market is expected to reach USD 557 million by 2028, growing at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2028. PR Newswire

- Regional Market Analysis: Asia Pacific is anticipated to hold the largest market share, accounting for approximately 40% of the total market revenue in 2023. WiseGuy Reports

- Key Players: Major companies in the shredder blades market include Eurotools Ltd., Augus Engineering Ltd., and Mastercut Cutting Systems Ltd. PR Newswire

Challenges and Future Outlook

Despite the positive trends, the industry faces several challenges:

- Sustainable Materials: There is an increasing demand for sustainable and eco-friendly materials in blade manufacturing. Addressing this need is crucial for companies aiming to align with environmental standards and consumer expectations.

- Evolving Recycling Standards: As recycling standards become more stringent, shredder blades must adapt to meet these requirements, ensuring compliance and efficiency.

- Technological Developments: Ongoing research and development are essential to drive further innovations in shredder blade technology, enhancing performance and expanding applications.

Conclusion

Advancements in shredder blades technology have significantly enhanced the efficiency and productivity of industrial recycling processes. These innovations have led to reduced operational costs, higher output rates, and longer-lasting equipment. As the industry continues to evolve, staying abreast of these developments is essential for companies aiming to maintain competitiveness and contribute to sustainable recycling practices.