Press Brake Dies: Precision Manufacturing for Sheet Metal Stamping

Press brake dies are indispensable in modern manufacturing, integral to sheet metal stamping operations. These tools facilitate the precise bending of metal sheets, delivering high-quality results across numerous applications. From automotive parts to intricate furniture designs, the accuracy and durability of press brake tooling significantly impact the final product. In this article, we’ll examine the technical specifications, diverse applications, and essential maintenance practices for press brake dies, providing valuable insights for optimizing your manufacturing processes. You might find several press brake dies for sale, but choosing the right one is crucial for efficiency and precision.

What is a Press Brake?

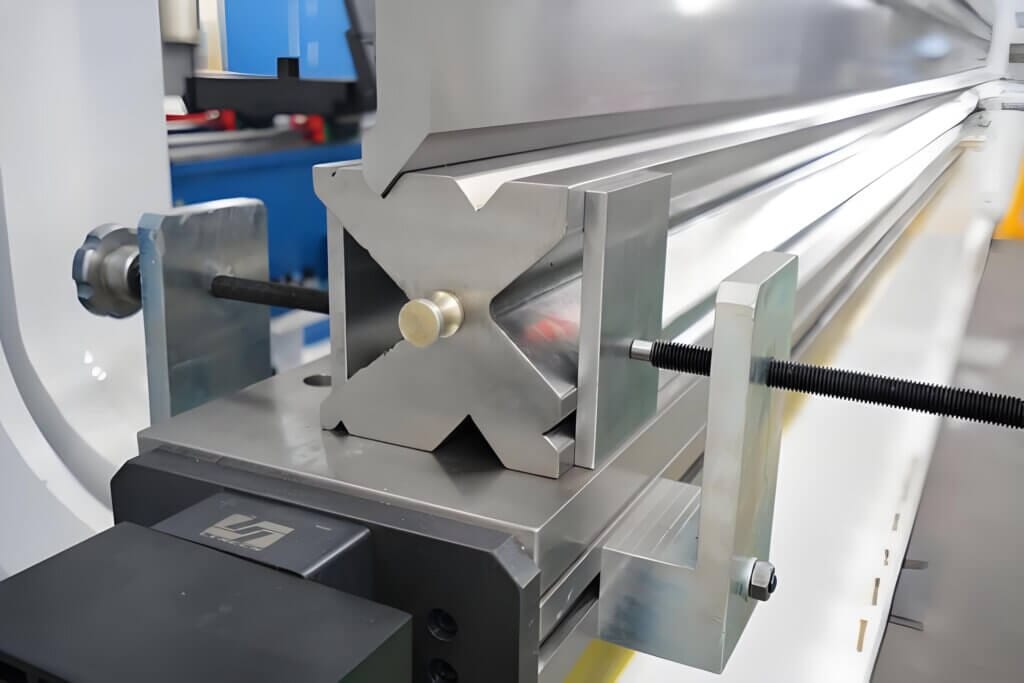

Before delving into the specifics of dies, it’s important to understand the machine they are used with. A press brake is a machine designed for bending metal sheets into precise angles. It comprises an upper ram and a lower bed. The metal sheet is placed between the upper and lower brake tooling, and the machine applies force, creating the desired form. Unlike a blanking machine, which cuts the metal, a press brake bends it.

Applications

Press brakes, equipped with the appropriate press brake dies, are essential in a wide range of industries:

- Automotive Industry: Manufacturing car body panels and structural components.

- Furniture Manufacturing: Creating frames for chairs, tables, and other furniture items.

- Electrical Equipment: Bending enclosures for electrical panels and appliances.

- Furniture and Appliance Fabrication: Producing various parts for appliances and furniture.

How to Run a Press Brake

Operating a press brake effectively involves several key steps:

- Material Preparation: Ensure the metal sheet has the correct dimensions and thickness.

- Tooling Setup: Select and install the correct press brake dies for the required bending angle.

- Bending Process: Load the metal sheet into the press and initiate the bending process, ensuring proper alignment.

- Quality Control: Inspect the bent metal sheet for accuracy, making any necessary adjustments.

Common Tooling Types

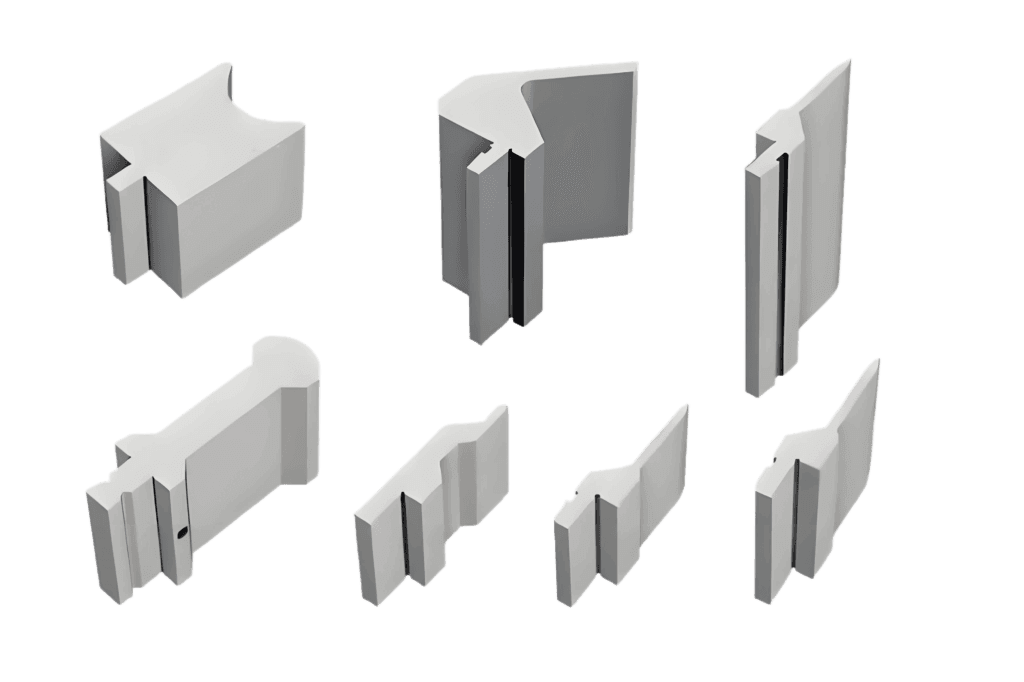

The versatility of a press brake is largely due to the variety of brake tooling available:

- Universal Upper Dies: General-purpose dies for various bending tasks.

- Heavy-Duty Lower Dies: Designed for high-force applications and thicker materials.

- Smear-Free Dies: Minimize surface damage on the metal sheet during bending.

- Precision R-Radius Dies: Create accurate rounded bends.

Technical Specifications and Benefits

Die Types

Different press brake dies are designed to cater to specific needs:

- Stainless Steel Press Brake Dies: Ideal for bending stronger metals and offer anti-corrosion properties.

- Aluminum Alloy Press Brake Dies: Lightweight, best suited for bending aluminum materials.

- Precision Arc Press Brake Dies: Designed for shaping specific R-Radius angles with high precision.

- Double V-Groove Press Brake Dies: Create deep V-shaped bends.

Material Selection

Our press brake dies are crafted from:

- High-Quality Specialty Steel: Ensuring durability and longevity.

- Rockwell Hardening: Providing enhanced hardness and wear resistance.

- Innovative Cam-Favor Techniques: Optimizing bending accuracy and efficiency.

Maintenance

Regular maintenance is essential to keep your press brake dies in optimal condition:

- Regular Cleaning: Prevents the buildup of metal chips and debris, which can affect bending accuracy.

- Precision Alignment: Ensures the bending edges are uniform, preventing irregular bends.

FAQs

- What is the process of making a sheet metal stamping press?

The process includes designing the die based on required dimensions, manufacturing the die from selected materials, testing for accuracy, and installing and debugging for proper operation. - How does a braking die work?

A brake die works by pressing a metal sheet between an upper and lower die. The machine applies pressure, forcing the metal to conform to a specific angle or shape. - What are some common issues with press brakes?

Common issues include blanks cutting inaccuracies, dies becoming dull or worn out, and overheating of the equipment. - How can I determine when to replace a press brake die?

Signs include persistently irregular bends, scrap parts indicating trimmed hard surges, and a significant increase in pressure required to achieve the desired bend angle. - Why are stainless steel press brake dies preferred?

Stainless steel provides superior wear resistance and durability, making it ideal for high-volume, high-precision applications.

Conclusion

Investing in high-quality press brake dies is crucial for achieving precision and efficiency in sheet metal stamping. Whether you are looking for press brake dies for sale or need expert advice on selecting the right brake tooling, understanding the technical specifications, applications, and maintenance practices will ensure superior results and longevity of your equipment.