Introduction

In the fast-paced world of modern packaging, efficiency is key. As industries around the globe continue to evolve, so do the tools that drive them forward. One of the most crucial components in packaging systems is the packaging stretch film blade. These blades are used to cut stretch films with precision and speed, ensuring packaging lines run smoothly and efficiently. With increased demand for high-quality, durable, and efficient packaging solutions, the role of stretch film blades has never been more important.

What Are Packaging Stretch Film Blades?

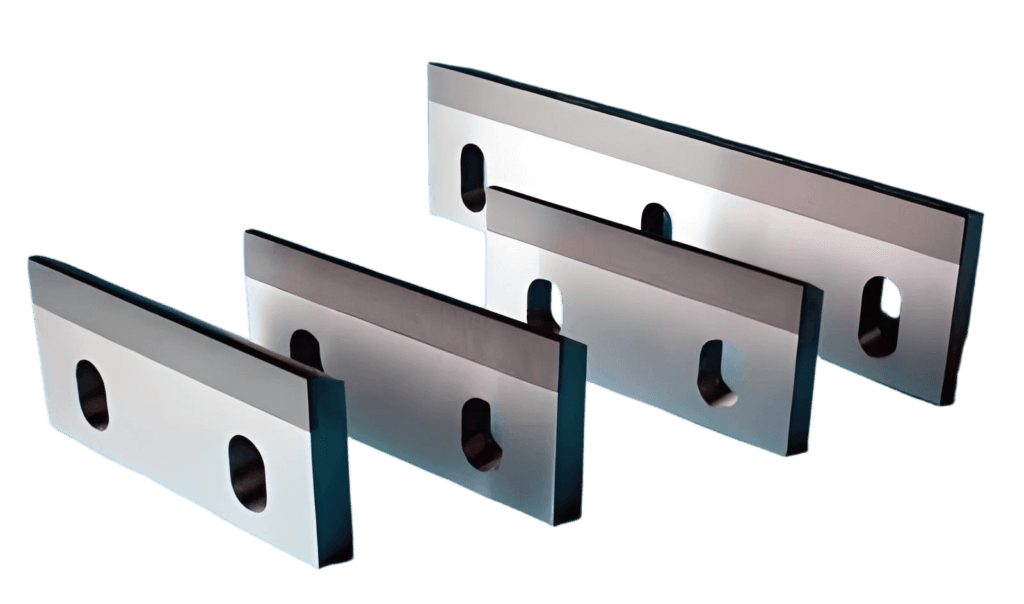

Packaging stretch film blades are specialized cutting tools designed to slice through stretch films and other plastic films commonly used in packaging. These blades are integral to packaging processes in industries such as food, pharmaceuticals, electronics, and consumer goods. They ensure that products are securely wrapped, preventing damage during transit while maintaining production efficiency.

The precision and sharpness of the blade are paramount to the overall quality of the packaging process. Whether used in manual or automated systems, the right stretch film blade can significantly enhance productivity and reduce operational costs.

Types of Packaging Stretch Film Blades

There are various types of packaging stretch film blades available, each with unique characteristics suited to different needs. Understanding the differences between them is crucial when selecting the right blade for your packaging requirements.

- Steel Blades: Often used in standard packaging applications, steel blades are durable and can be easily sharpened. They offer reliable performance for basic stretch film cutting tasks.

- Stainless Steel Blades: Ideal for applications where corrosion resistance is necessary, stainless steel blades are more expensive but provide a longer lifespan and better performance in harsh environments.

- Ceramic Blades: Known for their high precision and sharpness, ceramic blades maintain their edge for longer than steel counterparts. These blades are ideal for fine, detailed cuts and applications where minimal friction is required.

- High-Speed Steel Blades: These blades are designed to perform at higher speeds and in more demanding environments. They offer a superior balance of durability and sharpness, making them suitable for heavy-duty packaging lines.

How to Choose the Right Stretch Film Blade

Selecting the appropriate packaging stretch film blade depends on several factors, including the material being cut, the speed of the production line, and the durability required for the specific task.

- Material of the Blade: Choose blades made of materials that are compatible with the packaging films being used. For example, thicker films may require a stronger steel or ceramic blade to ensure clean, precise cuts.

- Durability: Consider how long the blade will need to last. A higher-quality material, like stainless steel or ceramic, can offer longer-term savings due to reduced replacement costs.

- Cut Precision: If your packaging needs high precision or involves intricate designs, a ceramic blade might be the best choice due to its superior sharpness and clean cuts.

Benefits of Using High-Quality Stretch Film Blades

The use of high-quality packaging stretch film blades comes with numerous advantages:

- Increased Cutting Efficiency: High-quality blades can cut through stretch films faster and with greater accuracy, increasing the speed of production lines and minimizing downtime.

- Longer Lifespan and Reduced Downtime: Blades made from durable materials like stainless steel or ceramic can last longer, meaning fewer replacements and less maintenance work. This leads to overall cost savings and less disruption in the production process.

- Consistent Cutting Quality: Premium blades ensure consistent, precise cuts with minimal defects, which is especially important in industries where packaging appearance matters, such as consumer electronics or food products.

Best Practices for Maintaining Packaging Stretch Film Blades

Proper maintenance is essential for ensuring that stretch film blades perform optimally over time. Here are some tips:

- Regular Cleaning: Accumulated film residue can dull the blade’s edge, making it less effective. Regularly cleaning the blade ensures that it stays sharp and functional.

- Sharpening and Replacing: Even the best blades will lose sharpness over time. Regularly inspecting blades for signs of wear and having them sharpened or replaced when necessary will ensure consistent performance.

- Avoiding Overuse: Overusing a blade beyond its intended capacity can lead to faster wear and tear. Ensure the blade is suited for the task at hand and replace it when it begins to show signs of wear.

Industry Trends and the Future of Stretch Film Blades

As automation continues to shape the packaging industry, the demand for more efficient and durable packaging tools, including packaging stretch film blades, is on the rise. New advancements in blade technology, such as coatings that enhance longevity or specialized designs for automated systems, are expected to further improve production lines.

Additionally, the trend toward sustainable packaging may influence the development of blades optimized for cutting biodegradable or recyclable materials. As the industry evolves, packaging stretch film blades will likely adapt to meet the changing needs of manufacturers and consumers alike.

Conclusion

In conclusion, packaging stretch film blades are integral to the smooth operation of packaging lines in various industries. Choosing the right blade, maintaining it properly, and understanding industry trends can lead to increased efficiency, reduced downtime, and significant cost savings. As the packaging industry continues to grow, these blades will play a critical role in meeting the demands of both producers and consumers.

By staying informed about advancements in blade technology and best practices for blade maintenance, companies can ensure they are using the most effective and durable tools for their packaging processes, helping them stay competitive in an ever-evolving market.