A knife grinding machine is indispensable for maintaining and sharpening various blades across numerous industries. From paper and metal to food and textiles, ensuring blades have a sharp, precise cutting edge is critical for operational efficiency and product quality. This article explores the key features, benefits, and diverse applications of knife grinding machines, providing valuable insights on how to select the right knife sharpener and achieve unparalleled blade performance.

What is a Knife Grinding Machine?

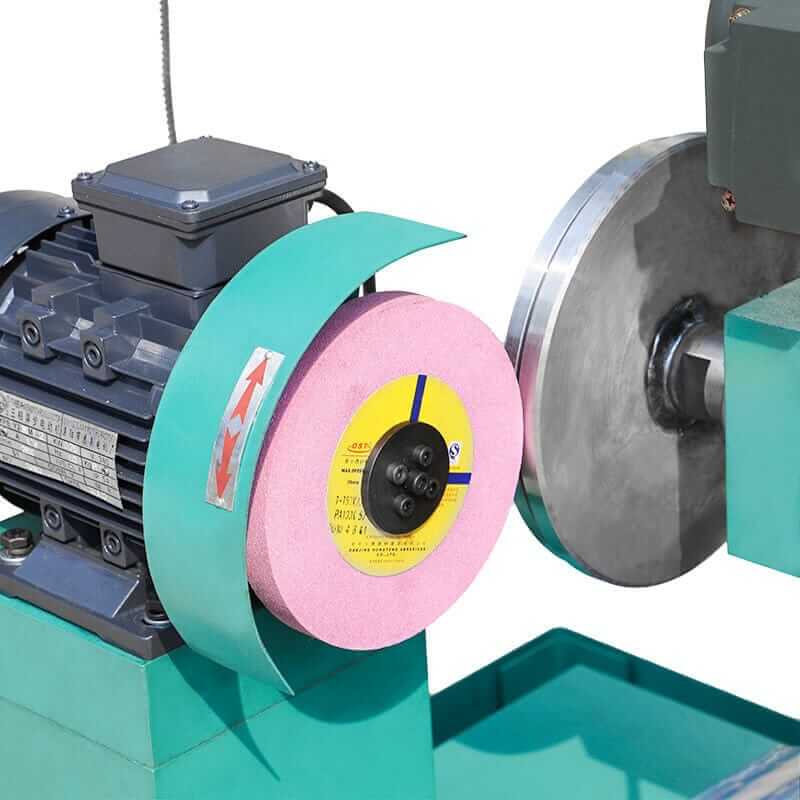

A knife grinding machine, also known as a knife sharpening grinder, is a specialized tool designed to sharpen and refine the edges of knives and blades. Unlike cutting machines that separate materials, grinding machines employ abrasive wheels to smooth and shape the blade, guaranteeing a sharp, precise cutting edge. These machines are essential for industries that rely on sharp blades for cutting, trimming, and processing materials.

Key Features:

- Precision Grinding: Engineered for accurate and consistent sharpening angles.

- Versatility: Suitable for a wide array of blade types and materials.

- Efficiency: Delivers a fast and effective knife sharpening process.

Types of Knife Grinding Machines

Different types of knife grinding machines cater to specific applications:

- Bench Grinders: Ideal for general-purpose knife sharpening with bench grinder, offering versatility and ease of use.

- Straight Knife Grinding Machinery: Specifically designed for sharpening straight blades with high precision. These are also known as Straight Knife Grinding machines.

- Circular Knife Grinding Machines: Precisely sharpen circular knife blades, ensuring consistent angles.

- Specialized Grinders: Custom-built for unique blade shapes and materials.

How to Sharpen Tools and Knives with a Bench Grinder

A bench grinder is a versatile tool for sharpening knives on a bench grinder. Here’s a guide on effectively using a bench grinder:

- Preparation: Clean the blade and inspect it for any damage.

- Grinding Wheel Selection: Select the appropriate grinding wheel based on the blade material. Carbide-tipped blades typically require a diamond wheel. To select a grinding wheel, start by identifying the material you’re working with.

- Angle Adjustment: Adjust the grinding machine to match the blade’s original bevel angle.

- Grinding Process: Pass the blade consistently over the grinding wheel, avoiding excessive material removal.

- Deburring: Remove any burrs formed during the sharpening process.

- Inspection and Testing: verify uniform sharpness and balance.

How to Select a Knife Sharpener

Selecting the right knife sharpener hinges on several considerations:

- Blade Type: Different blades need specific sharpening tools and techniques.

- Material: The blade material affects the choice of grinding wheel.

- Frequency of Use: High-volume sharpening may necessitate a more robust machine.

- Desired Precision: For high-precision tasks, consider professional sharpening machines.

Technical Specifications and Features

Precision and Control

High-grade grinding machines often boast a PLC and touchscreen control system with a servo system for vertical feed and infinitely variable speed for the grinding head. This enables the machine to automatically adjust to optimal grinding parameters, fitting various grinding needs.

Material and Build

The bed of the grinding machine is crafted from thickened steel plates, welded as a single unit, and tempered to eliminate stress, ensuring the machine body remains stable. High-precision linear guides and scraping processes are utilized to enhance operational accuracy and reduce grinding errors.

Components

- Grinding Head: Often equipped with a high-speed lifting motor for swift wheel changes.

- Platform: Utilizes high-precision lead screws, linear guides, and dovetail rails for accurate tool feeding.

- Blade Section: Employs a high-precision Morse taper internal hole spindle and an efficient reduction motor for smooth rotation.

Common Applications of Knife Grinding Machines

- Paper Industry: Sharpening blades for cutting and trimming paper rolls.

- Metal Industry: Maintaining blades for cutting steel and other metals.

- Wood and Forestry: Sharpening blades for cutting and processing wood.

- Food Processing: Ensuring knives are sharp for safe and efficient food preparation.

- Textile Industry: Keeping blades sharp for cutting fabrics and textiles.

Benefits of Using Professional Knife Grinding Machines

- Increased Efficiency: Sharp blades cut more cleanly and quickly.

- Improved Precision: Consistent sharpening angles ensure uniform cuts.

- Reduced Waste: Sharp blades minimize material waste and rework.

- Enhanced Safety: Sharp knives require less force, reducing the risk of accidents.

MAIDECAL: Your Partner in Precision Sharpening Solutions

MAIDECAL provides a wide array of knife grinding machines designed for optimal precision and efficiency. Our machines are customizable to meet the specific needs of various industries, ensuring peak blade performance and longevity. Contact our sales team today to explore how we can help you achieve the best sharpening solutions for your blades .