Understanding High-Speed Steel (HSS)

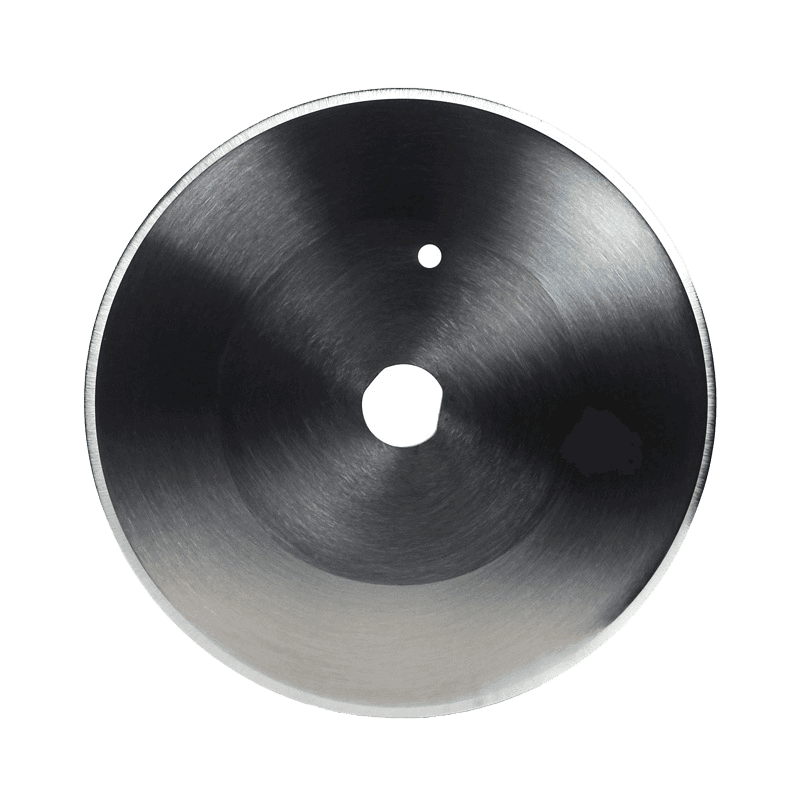

High-speed steel (HSS) is a type of tool steel that is renowned for its exceptional hardness and ability to withstand high temperatures without losing its cutting edge. HSS is primarily composed of iron, with a blend of carbon and various alloying elements such as tungsten, molybdenum, cobalt, and chromium. These elements are critical for enhancing the wear resistance and toughness of the steel, making it a popular choice for manufacturing cutting tools, including high-speed steel cutter blades.

One of the significant advantages of HSS is its ability to maintain its hardness at elevated temperatures, a characteristic that allows it to perform effectively during high-speed machining processes. Unlike conventional carbon steel, HSS can be heat treated to achieve a hardness level between 62 and 66 Rockwell, a feature that grants it superior cutting performance. This performance is particularly beneficial in industrial applications where precision and durability are paramount.

High-speed steel is available in various grades and types, including M2, M35, and T1, each specially formulated to serve specific cutting applications. For instance, M2 is widely used in manufacturing drill bits and milling cutters, while M35, which incorporates cobalt for added toughness, is ideal for more demanding operations. In comparison to carbide, which is much harder and suited for specific conditions, HSS offers greater resilience and is often more cost-effective for general-purpose cutting tasks.

Additionally, HSS has a lower brittleness compared to other materials such as carbide, which enables it to absorb shocks and impacts without chipping. This property makes high-speed steel cutter blades an excellent choice for a variety of machining tasks, providing both efficiency and reliability in the process. Today, HSS remains a preferred material in the industry due to its balance of hardness, toughness, and cost-effectiveness.

Advantages of High-Speed Steel Cutter Blades

High-speed steel (HSS) cutter blades are widely renowned for their superior performance in various cutting applications, making them a popular choice among industry professionals. One of the primary advantages of HSS blades is their remarkable durability and longevity. Constructed from high-carbon steel and alloyed with other metals, these blades endure wear and tear better than many alternatives, resulting in a longer lifespan. This durability translates to less frequent replacements, ultimately reducing operational downtime and maintenance costs.

Another significant benefit of high-speed steel cutter blades is their exceptional heat resistance. When cutting through tough materials, friction generates heat, which can lead to blade failure. However, HSS blades are specifically crafted to retain their hardness at elevated temperatures, allowing them to maintain cutting efficiency without compromising integrity. This heat resistance enables them to perform effectively in high-speed machining operations, ensuring consistent results and prolonged use.

Versatility is yet another advantage associated with high-speed steel blades. They excel in cutting various materials, including metals, plastics, and wood, making them a valuable tool in numerous industries. Their adaptability allows operators to utilize the same blade for multiple tasks, streamlining workflow and reducing the need for specialized cutting tools. For example, many machinists and woodworkers report finding HSS blades particularly beneficial for applications requiring finisher-like cut quality, showcasing their versatility in delivering precise results.

Cost-effectiveness also plays a critical role in the appeal of high-speed steel cutter blades. While the upfront investment may be slightly higher than for other blade materials, the longevity and reduced replacement frequency often offset initial expenses. As a result, many businesses find that adopting HSS blades leads to significant long-term savings. Testimonials from industry professionals highlight their satisfaction with both the performance and value of HSS blades in real-world applications, reinforcing the notion that they are an optimal choice for various cutting tasks.

Applications of High-Speed Steel Blades

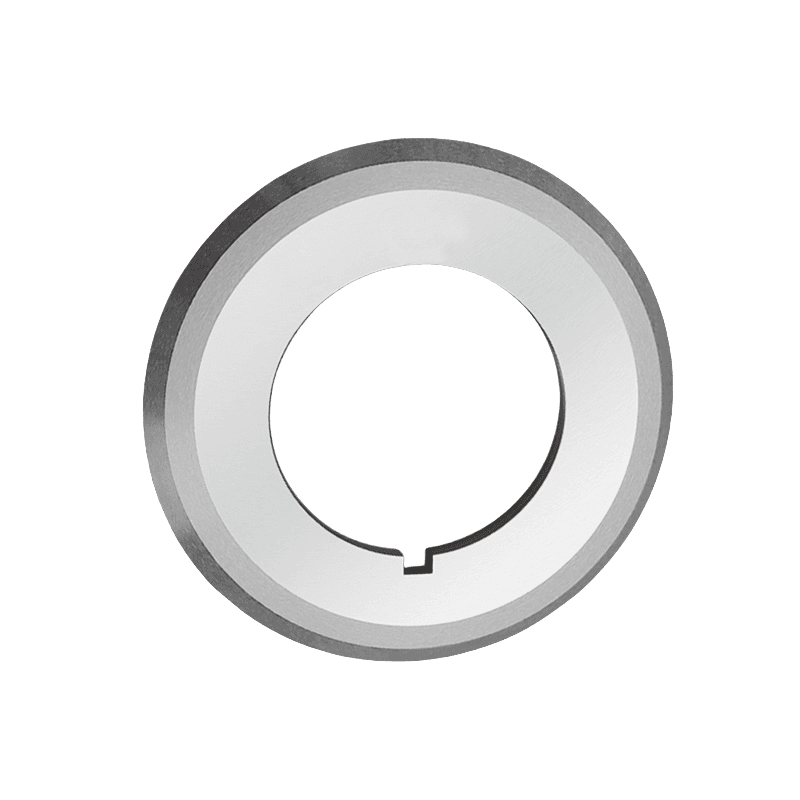

High-speed steel cutter blades are renowned for their versatility and performance across a variety of industrial applications. Their unique composition, which consists of tungsten, molybdenum, and other elements, allows these blades to maintain sharpness and durability even under severe working conditions. This makes them an ideal choice for many sectors, including manufacturing, woodworking, metalworking, and machining.

In the manufacturing sector, high-speed steel blades are frequently used in cutting tools that process various materials, due to their resistance to wear and heat. These blades are essential for high-volume production environments where precision and efficiency are paramount. For instance, they are commonly found in lathes and milling machines, where they can achieve fine tolerances and intricate designs.

Woodworking is another field where high-speed steel cutter blades excel. They provide clean cuts and long-lasting performance when used in saws and routers, making them suitable for furniture making, cabinetry, and other woodcraft projects. Because of their ability to retain edges longer, craftsmen prefer HSS blades for applications that require repeated cutting into hard and softwoods alike.

In the metalworking arena, high-speed steel blades are invaluable. Their ability to withstand the high temperatures generated during machining operations means they can effectively cut through harder metals, such as stainless steel and titanium. They are often employed in drilling, turning, and shaping applications, where surface finish and cutting speed are critical to project success.

Finally, when it comes to machining processes, high-speed steel cutter blades are favored for their efficiency. These blades can process through various materials swiftly, making them ideal for operations that demand speed without compromising on precision. Overall, understanding the diverse applications of high-speed steel blades can help professionals identify if they are the right fit for their specific projects.

Making the Right Choice for Your Projects

When it comes to selecting the right cutting tools for your projects, understanding the nuances of high-speed steel cutter blades is essential. These tools offer notable advantages for various applications, but their suitability often depends on specific project requirements, budget constraints, and the materials being utilized.

Firstly, consider the nature of your project. High-speed steel blades are ideal for tasks requiring durability and precision on harder materials. If you’re working with metals such as stainless steel or other tough alloys, HSS blades can provide the necessary cutting performance. However, for softer materials like wood or plastics, alternative blade types, such as carbide-tipped blades, might be more efficient and economical. Evaluating the material compatibility will help to determine whether high-speed steel blades are indeed the best choice for your needs.

Budget is another significant factor in your decision-making process. High-speed steel cutter blades can be more expensive upfront compared to their counterparts, yet their durability often leads to a longer service life, which can offset costs over time. It is important to assess the initial investment versus the long-term benefits. Often, opting for high-quality blades in the short term can lead to cost savings if they provide superior performance and longevity.

Lastly, it is crucial to compare HSS blades with other options available in the market. For instance, carbide blades, while generally more robust and suitable for heavier-duty applications, can also be more fragile. Assessing the specific demands of your project and matching them to the right blade type can lead to improved efficiency and results.

Ultimately, taking the time to consider these factors will empower you to select the best cutting tool for your specific applications, ensuring optimal performance and satisfaction with your project outcomes.