Understanding Heavy-Duty Cutter Blades

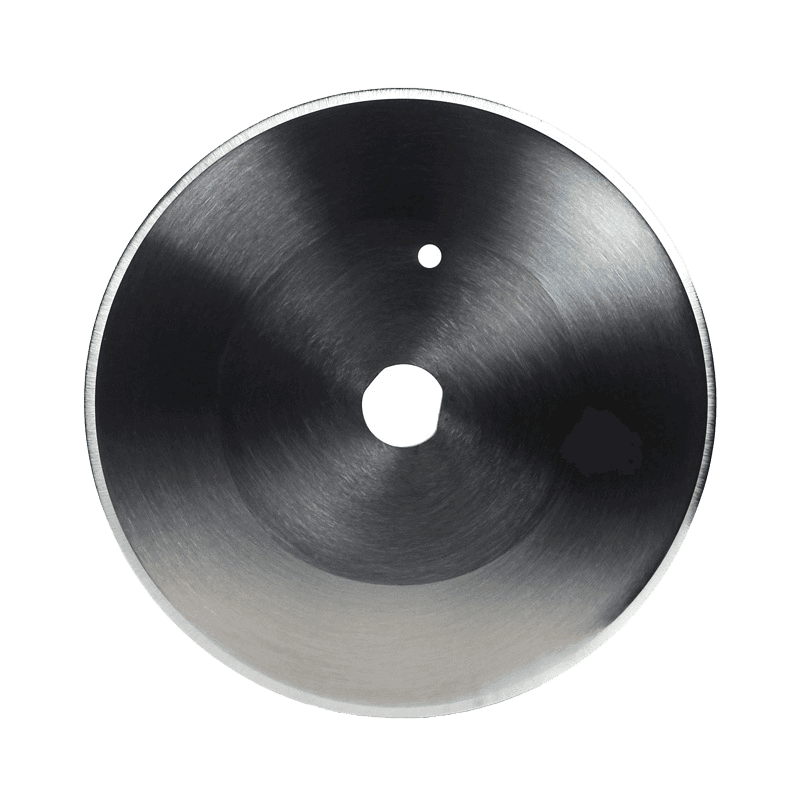

Heavy-duty cutter blades are crafted for resilience and efficiency, designed to withstand the rigors associated with demanding tasks. Generally manufactured from high-grade materials such as high-speed steel or carbide, these blades possess the robustness required for cutting through tough materials. The unique composition of heavy-duty blades distinguishes them from standard blades, as they are engineered to handle increased stress and prolonged use without significant wear.

The design of heavy-duty cutter blades often includes features such as thicker edges, optimized geometries, and specialized coatings that enhance performance and durability. These attributes significantly contribute to their ability to endure high-impact situations and mitigate the risks of chipping or breaking. For instance, many heavy-duty cutter blades are treated with surface hardening techniques which add an additional layer of resilience, providing operators with consistency in performance over time.

While standard cutter blades may suffice for less demanding tasks, heavy-duty variants are indispensable in industries that require cutting through materials such as metals, hardwoods, and other dense composites. In applications ranging from construction and manufacturing to woodworking, utilizing durable heavy-duty cutter blades not only enhances productivity but also ensures better precision and safety.

The specifications of these blades often include measures such as higher RPM ratings and increased cutting depths, tailored to meet the rigorous demands of specific tools and machinery. Differentiating between standard and heavy-duty blades is essential, as the former may not withstand the stress experienced during intensive operations, leading to frequent replacements and downtime.

In summary, understanding the attributes and capabilities of heavy-duty cutter blades is vital for achieving optimal results in various applications. Their unique construction undoubtedly plays a significant role in prolonging tool life and ensuring efficient operation across industries.

Benefits of Using Durable Cutter Blades

The use of durable heavy-duty cutter blades offers numerous advantages, particularly in commercial and industrial applications. One significant benefit is cost-effectiveness. While the initial investment in high-quality, long-lasting blades may be higher compared to standard options, these durable tools tend to last considerably longer, reducing the frequency of replacements. Over time, the savings accumulate as businesses experience fewer interruptions and lower material costs associated with blade replacement.

Additionally, using durable cutter blades minimizes downtime. In industries where productivity is paramount, the efficiency afforded by blades that resist wear and tear is invaluable. A longer tool life inherently means less time spent on routine maintenance and blade changes, allowing operators to focus on their core tasks. For example, production lines utilizing superior blades can maintain continuous output, thereby enhancing overall operational efficiency.

Another important aspect is the enhanced performance of durable heavy-duty cutter blades when working with tough materials. Whether cutting through dense wood, metal, or composite materials, these blades are designed to handle rigorous demands without compromising on cutting speed or quality. Their robust construction allows them to maintain edge sharpness longer, which is crucial for achieving clean cuts and preventing material damage. For instance, a construction company using high-quality blades reported fewer defects in their materials, consequently leading to improved project outcomes.

Furthermore, improved precision is a vital benefit of using durable cutter blades. These blades are engineered to provide consistent cuts, which is essential in achieving desired specifications and tolerances. The precision offered by such blades reduces waste and rework, leading to even greater operational efficiency. By employing durable cutter blades, businesses can ensure high-quality results that meet the expectations of clients and regulatory standards.

Choosing the Right Cutter Blades for Your Needs

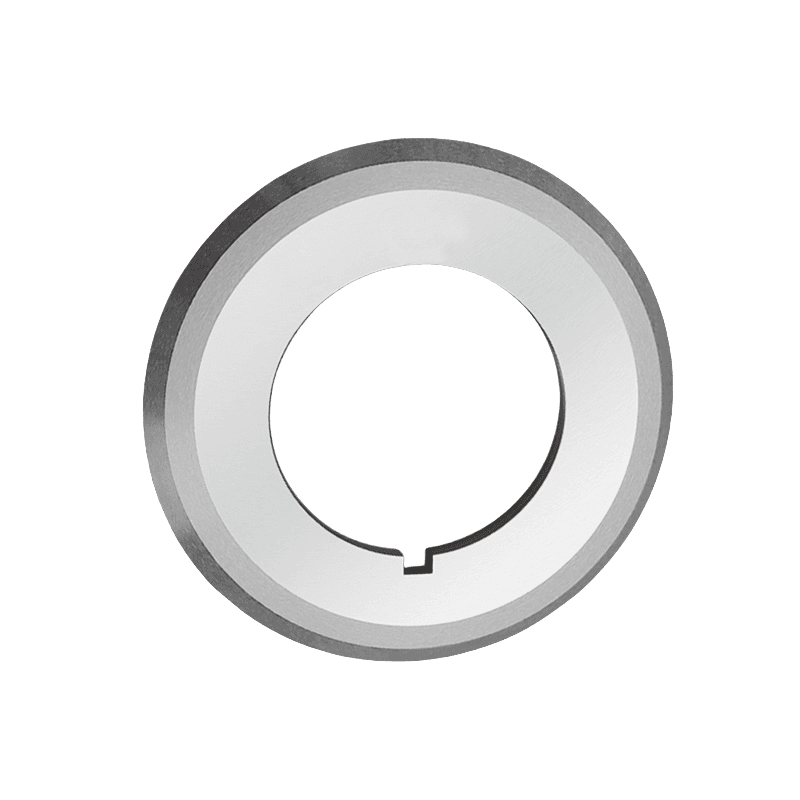

Choosing the appropriate durable heavy-duty cutter blades is essential for ensuring optimal performance in various applications. To make an informed decision, several critical factors should be taken into account, starting with the size of the blades. The diameter and thickness of the cutter blades should match the specifications of the tool being used. Using a blade that is too large or too small can not only hinder functionality but also impact safety during operation.

Compatibility with tools is another important consideration. It is paramount that the selected cutter blades fit seamlessly with the equipment they are intended for, whether it be power saws, cutting machines, or manual hand tools. One should always check the manufacturer’s recommendations to ensure that the heavy-duty cutter blades are suitable for their specific tools.

The material composition of the blades plays a crucial role in determining their longevity and cutting effectiveness. Options such as high-speed steel, carbide, and even bi-metal constructions offer various benefits depending on the application. For instance, carbide-tipped blades are known for their exquisite durability and precision in cutting through harder materials, making them ideal for industrial tasks. In contrast, high-speed steel blades may be more appropriate for softer materials or general-purpose use.

Moreover, considering the intended use case is vital. Heavy-duty cutter blades designed for heavy materials will require different specifications than those intended for lightweight projects. By identifying the primary materials to be cut, users can narrow down options that will excel in their specific application.

In conclusion, selecting the right durable heavy-duty cutter blades involves a careful assessment of blade size, tool compatibility, material type, and intended use case. By taking the time to evaluate these factors, consumers can ensure they make informed purchasing decisions that contribute to greater efficiency and longevity of their tools.

Where to Find Quality Heavy-Duty Cutter Blades

Finding quality durable heavy-duty cutter blades is essential for ensuring effective and efficient cutting tasks, whether in industrial settings or for personal use. A wide variety of options exists for sourcing these blades, ranging from well-known tool brands to reputable online retailers.

One reliable avenue for obtaining durable heavy-duty cutter blades is through established tool manufacturers. Brands such as Bosch, DEWALT, and Stanley are recognized for producing high-quality cutting tools that meet professional standards. These companies often provide a range of blade options tailored to different cutting needs, ensuring that users can find a suitable solution for their specific requirements.

Additionally, hardware and home improvement stores, including Lowes and Home Depot, are excellent places to find durable blades. These retailers typically stock a variety of brands and blade types, making it easy for customers to compare products directly. Many of these stores also offer knowledgeable staff who can provide valuable insights on which blades work best for particular applications, ensuring informed purchasing decisions.

Online marketplaces like Amazon and eBay also present a convenient option for purchasing heavy-duty cutter blades. Here, buyers can access an extensive range of products, often accompanied by customer reviews which can give insight into the performance and durability of different blades. It is also a good practice to check for warranties and after-sales support when purchasing online, as these terms can provide additional reassurance about the product’s quality.

Finally, customer feedback is crucial when choosing durable heavy-duty cutter blades. Reading reviews can help gauge the reliability of specific brands and retailers. Prioritizing suppliers with a solid reputation will ultimately contribute to enhanced productivity and tool longevity.