The Essential Guide to Cutter Blades: Maximizing Performance and Lifespan

Cutter blades are the unsung heroes of countless tasks, playing a vital role in everything from opening packages to intricate industrial cutting processes. Selecting the right blade and maintaining it properly are crucial for efficiency, safety, and cost-effectiveness. Let’s dive into the world of cutter blades.

Utility Knives & Blades: A Versatile Cutting Solution

The term “cutter blade” often brings to mind the ubiquitous utility knife. These knives, known for their retractable blades and versatility, are staples in workshops, warehouses, and homes. They handle a wide range of materials, making them indispensable tools.

What are the different types of knife blades?

Knife blades come in a variety of shapes, sizes, and materials, each designed for specific applications. Here are some common types:

- Straight Blades: Ideal for general-purpose cutting, offering a clean and precise cut on various materials.

- Serrated Blades: Perfect for sawing through tougher materials like cardboard or rope, providing aggressive cutting action.

- Curved Blades: Designed for slicing and skinning, commonly found in hunting and culinary knives.

- Specialty Blades: Include blades for specific tasks like cutting drywall, linoleum, or carpet.

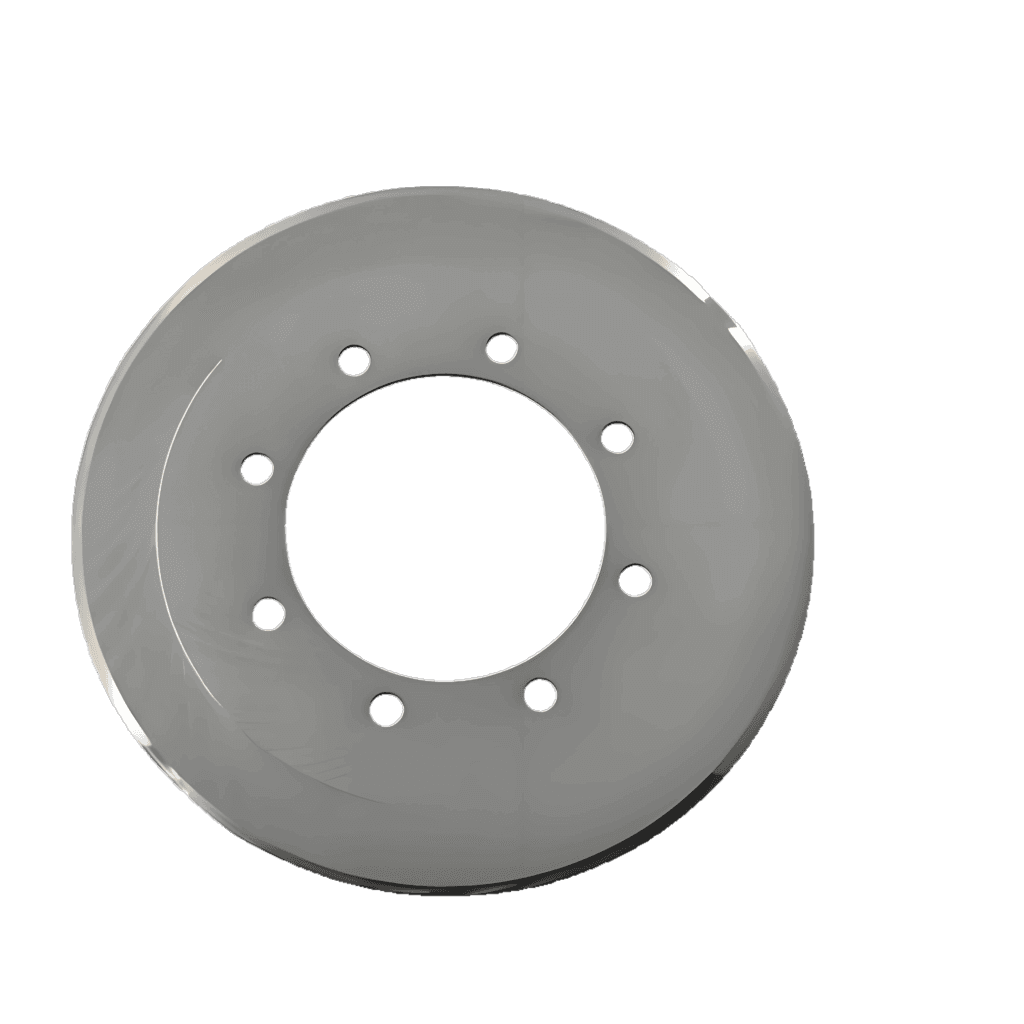

- Slitting circular blades: Ideal for slitting applications requiring precision and clean cuts.

- Wood chipping blades: Used in wood processing to create wood chips for various applications.

Understanding the Importance of Blade Material

The material of a cutter blade significantly impacts its performance and longevity. Common materials include:

- Carbon Steel: Offers excellent sharpness and is easy to sharpen, but is susceptible to rust.

- Stainless Steel: Provides good corrosion resistance and edge retention, making it a popular choice for everyday use.

- Alloy Steel: Enhances the durability and reliability of blades.

- High-Speed Steel (HSS): Offers exceptional wear resistance and is suitable for high-speed cutting applications.

- Ceramic: Extremely hard and wear-resistant, retaining sharpness for a long time, but can be brittle.

Maintaining Your Cutter Blade: Preventing Rust and Dullness

Proper maintenance is essential to prolong the life of your cutter blades and ensure optimal performance.

How should I keep my blades from rusting?

Rust is a common enemy of cutter blades, especially those made of carbon steel. Here’s how to prevent it:

- Clean After Use: Wipe the blade clean after each use to remove any moisture or residue.

- Dry Thoroughly: Ensure the blade is completely dry before storing it.

- Apply Oil: Apply a thin coat of oil (e.g., mineral oil, gun oil) to the blade to create a protective barrier against moisture.

- Store Properly: Store blades in a dry environment, away from humidity.

How to fix a dull box cutter blade?

A dull blade is not only inefficient but also dangerous, as it requires more force to cut, increasing the risk of slippage. Here’s how to address a dull box cutter blade:

1.Replacing the Blade: The easiest and often safest solution is to replace the blade. Many utility knives feature segmented blades that can be snapped off to reveal a fresh, sharp section.

- How to change box cutter blade?

- How to change blade in box cutter?

- How to change the blade on a box cutter?

Most utility knives have a mechanism to release the old blade and insert a new one. Consult your knife’s manual for specific instructions. Generally, this involves:

- Retracting the blade fully.

- Locating the blade release button or lever.

- Carefully removing the old blade.

- Inserting the new blade, ensuring it’s properly seated.

- Retracting and extending the blade to ensure it’s locked in place.

- How to put a blade in a box cutter? Follow the same steps as above for changing the blade.

2.Sharpening the Blade: If the blade is not severely damaged, you can sharpen it using a sharpening stone or honing steel.

- Secure the blade in a vise or clamp.

- Hold the sharpening stone at a consistent angle (usually around 20-30 degrees).

- Move the blade across the stone in a smooth, even motion.

- Repeat on both sides of the blade until sharp.

How to sharpen pipe cutter blades?

Sharpening pipe cutter blades requires a slightly different approach due to their circular shape. Here’s a general method:

- Remove the Blade: Carefully remove the blade from the pipe cutter.

- Secure the Blade: Use a vise or clamp to hold the blade securely.

- Use a File or Grinding Tool: Employ a fine-toothed file or a specialized grinding tool designed for circular blades.

- Maintain the Angle: Follow the original bevel angle of the blade while sharpening.

- Deburr: Remove any burrs or sharp edges created during sharpening.

- Reinstall: Carefully reinstall the sharpened blade back into the pipe cutter.

Working with Tough Materials

With what do you cut thick cardboards?

Cutting thick cardboard requires a sharp, sturdy blade and a controlled cutting technique. Here are some recommendations:

- Utility Knife with a Heavy-Duty Blade: A utility knife with a thick, durable blade is a great option for cutting thick cardboard.

- Serrated Blade: The serrated edge helps to grip and saw through the cardboard fibers more easily.

- Box Cutter: Designed specifically for cutting boxes, these cutters often have a comfortable grip and a sharp blade.

For cutting cardboard, selecting high-quality alloy steel and employing advanced manufacturing processes enhance blade durability and reliability. Unique edge treatments further reduce cardboard layering and burr formation, ensuring clean, smooth cuts.

Ensuring Precision in High-Precision Industries

In industries demanding high precision, such as electronics manufacturing, the precision manufacturing process of cutter blades becomes paramount. Ultra-fine edges guarantee smooth cuts without damaging circuit components, reducing scrap rates.The use of anti-static materials ensures product performance, while excellent durability minimizes blade replacements, enhancing production efficiency.

The Advantage of Our Cutter Blades

Our company is dedicated to providing high-quality cutter blades tailored to meet diverse customer needs. We prioritize blade quality, starting with the procurement of premium materials and rigorously testing each batch of raw materials.Advanced processes and high-precision equipment are employed in production, with strict quality control and testing at every stage, covering critical metrics such as hardness, toughness, sharpness, and dimensional tolerances.Our facilities are equipped with professional testing equipment and skilled technicians to ensure that every blade meets the highest standards before leaving the factory.

We also offer customization services to meet specific requirements. Customers can contact our sales team via phone, email, or online form to specify dimensions, shape, material, special features (such as processes, coatings, etc.), and application scenarios.Providing drawings, sketches, or specifications greatly assists us in understanding your needs.Our engineering team will evaluate the design and communicate with you to ensure the customized blade meets your expectations and machine requirements.

Conclusion

Cutter blades are essential tools with a wide range of applications. By understanding the different types of blades, practicing proper maintenance, and using the right techniques, you can maximize their performance and lifespan. Whether you’re a professional tradesperson or a DIY enthusiast, investing in quality cutter blades and taking care of them will ultimately save you time, money, and frustration.