📌 Introduction: Why is Corrugated Cardboard Essential?

Corrugated cardboard is one of the most widely used packaging materials in the world. Its lightweight, durable, and eco-friendly nature makes it an ideal choice for shipping, retail packaging, and industrial applications. Whether you’re looking for a sustainable packaging solution or a material that offers strength and versatility, corrugated cardboard stands out as an exceptional option.

In this article, we will explore:

- The manufacturing process of corrugated cardboard.

- Different types and classifications based on structure and usage.

- Key industries that rely on corrugated cardboard.

- Environmental benefits and recycling processes.

- How to choose the right type of corrugated board for your business needs.

🏭 How is Corrugated Cardboard Made?

The production process of corrugated cardboard involves several intricate steps to ensure quality and durability:

- Pulping & Paper Production 📄

- Raw wood fibers are processed into large sheets of paper.

- Recycled materials can also be used to create eco-friendly cardboard.

- Corrugation Process 🔄

- A machine called a corrugator applies heat and pressure to shape the paper into a wave-like structure (fluting).

- The fluted paper is glued between two flat linerboards to form the corrugated board.

- Cutting & Shaping ✂️

- The cardboard sheets are cut into different sizes depending on the intended application.

- Some boxes include perforations, scoring, or creases for easier folding.

- Printing & Finishing 🎨

- Businesses may print logos, barcodes, and branding designs directly onto the surface.

- Protective coatings (such as wax or laminates) can be applied to enhance durability.

- Quality Control & Shipping 🚚

- The final products undergo rigorous quality testing to ensure strength and reliability.

- Large rolls or pre-cut boxes are then shipped to various industries.

🔹 Types of Corrugated Cardboard

Different industries require different types of corrugated boards, classified based on flute thickness and wall structure:

🏗️ Based on Flute Size:

| Flute Type | Flute Thickness | Best Used For |

|---|---|---|

| A-Flute | 4.8mm – 5.5mm | Heavy-duty packaging, stacking strength |

| B-Flute | 2.1mm – 3.2mm | Food & beverage packaging, die-cut designs |

| C-Flute | 3.5mm – 4.0mm | Standard shipping boxes |

| E-Flute | 1.1mm – 1.8mm | Retail boxes, lightweight packaging |

| F-Flute | 0.6mm – 1.0mm | High-end retail, protective packaging |

📦 Based on Wall Structure:

| Wall Type | Description | Common Uses |

| Single Face | One linerboard + one fluted sheet | Cushioning & inner packaging |

| Single Wall | Two linerboards + one fluted sheet | Standard shipping boxes |

| Double Wall | Three linerboards + two fluted sheets | Heavy-duty storage & transport |

| Triple Wall | Four linerboards + three fluted sheets | Industrial applications, bulk containers |

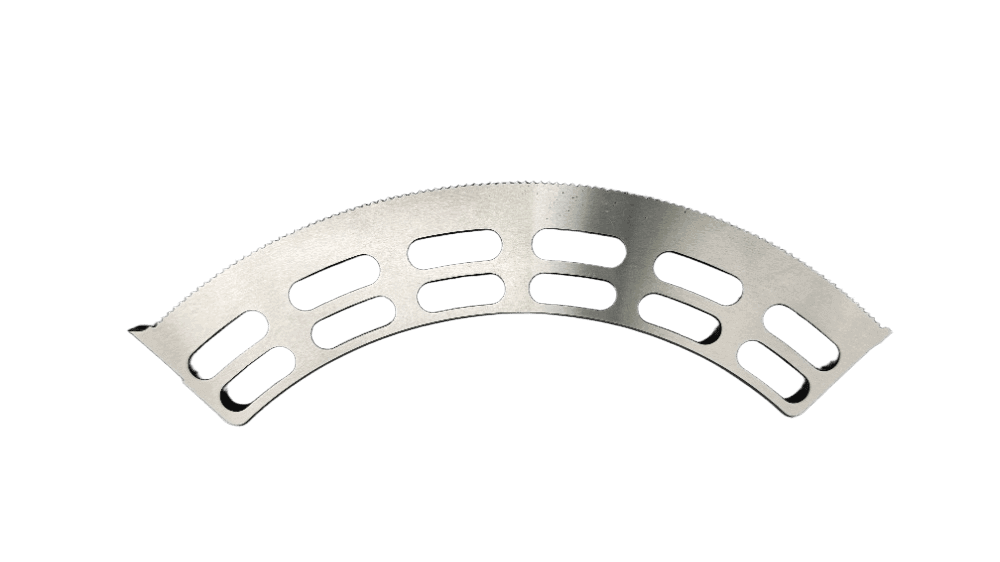

🛠️Corrugator Blade Specifications

📦 Industries That Rely on Corrugated Cardboard

Corrugated cardboard serves as a backbone for multiple industries due to its cost-effectiveness and protective qualities:

🚛 Logistics & E-Commerce

- Protects fragile items during shipping.

- Customizable sizes reduce shipping costs.

- Used by companies like Amazon, eBay, and Walmart.

🍕 Food & Beverage Industry

- Pizza boxes, beverage carriers, takeout containers.

- Meets FDA food safety standards.

- Coatings available to resist grease and moisture.

🛒 Retail & Branding

- Eye-catching point-of-sale displays.

- High-quality custom printed boxes.

- Sustainable packaging solutions for brands.

📦 Industrial & Heavy-Duty Packaging

- Used for automotive parts, appliances, and machinery.

- Triple-wall corrugated cardboard replaces wooden crates.

- Offers high impact resistance.

🌿 Environmental Impact & Sustainability of Corrugated Cardboard

Corrugated cardboard is an eco-friendly alternative to plastic packaging. Here’s why:

✅ 100% Recyclable & Biodegradable ♻️ ✅ Made from Renewable Resources 🌱 ✅ Reduces Carbon Footprint 🏭 ➡️ 🌍 ✅ Less Energy-Intensive Production 🔋 ✅ Can Be Reused Multiple Times 🔄

Recycling Fact: Over 80% of all corrugated cardboard is recycled globally, making it one of the most sustainable packaging options available.

🔍 Choosing the Right Corrugated Cardboard for Your Needs

When selecting corrugated cardboard for packaging or storage, consider these factors:

🔹 Weight Capacity – How much weight does the box need to hold?

🔹 Moisture Resistance – Will it be exposed to humidity or liquids?

🔹 Printing Requirements – Does it need branding, barcodes, or labels?

🔹 Storage & Stacking – Will it be stored for long durations?

📞 Contact Us for High-Quality Corrugated Cardboard Solutions!

📞 Call us at: +86-137-2123-6496

📧 Email us at: info@maidecal.com

🌍 Visit our website: www.maidecal.com

🚀 Upgrade your packaging with strong, sustainable, and cost-effective corrugated cardboard today!