Introduction

In industrial operations where speed and precision are crucial, choosing the right tools can make all the difference. Custom industrial blades for high-speed cutting are integral to improving operational efficiency and minimizing downtime. The selection of these blades directly influences not only the quality of cuts but also the longevity of machinery, maintenance costs, and overall productivity. Ensuring that the right custom blades are chosen for high-speed cutting applications can optimize performance, reduce costs, and deliver more accurate results. This article explores the pivotal role that blade selection plays in elevating operational capabilities and preventing unnecessary interruptions.

Understanding High-Speed Cutting

What defines high-speed cutting in industrial applications?

High-speed cutting refers to the process of cutting materials at elevated speeds, often exceeding typical cutting rates. In industries such as packaging, automotive, and paper processing, high-speed cutting is essential for maintaining high throughput. These processes often involve the use of advanced cutting machines designed to operate at speeds far beyond traditional equipment. High-speed cutting demands precise synchronization of machinery, blades, and materials to ensure both the integrity of the cuts and the safety of operations.

Key challenges and demands of high-speed cutting

The primary challenges of high-speed cutting lie in maintaining accuracy while operating at rapid speeds. With the increase in cutting speed, there’s a heightened risk of wear and tear on cutting tools, vibrations, and heat generation. These factors can cause tool degradation, inaccurate cuts, and even damage to the materials being processed. Therefore, choosing the right custom industrial blades is crucial for managing these challenges and ensuring the blades can withstand the stresses of high-speed cutting without compromising performance.

The Role of Custom Industrial Blades

Why custom blades are preferred for high-speed cutting

Custom industrial blades are specifically designed to meet the unique needs of high-speed cutting processes. Unlike generic blades, custom blades are tailored to the precise specifications of the materials being cut, the type of machine in use, and the desired output. By incorporating custom designs, manufacturers can ensure that their cutting tools offer superior durability, efficiency, and precision, reducing the risk of costly downtime or machinery damage. Custom blades are engineered to maximize performance, offering a perfect fit for a particular operation.

Advantages of custom blades over standard blades in specific applications

While standard industrial blades may work for general cutting tasks, they often fall short when it comes to high-speed applications. Custom blades are designed to address specific challenges, such as increased wear, heat buildup, and vibrations that occur during high-speed cutting. Additionally, custom blades can be optimized for specific materials—whether they are metal, plastic, or paper—to ensure better cutting quality and longer tool life. By offering a better match between blade design and cutting requirements, custom blades help minimize operational issues like poor cut quality, reduced machine lifespan, and high maintenance costs.

Key Factors in Choosing the Right Custom Industrial Blades

Material considerations: Steel, carbide, and other materials

The material of the blade is one of the most crucial factors in ensuring optimal performance in high-speed cutting. Steel blades are often chosen for their strength and sharpness but can wear quickly when used on hard materials. Carbide, on the other hand, is favored for its hardness and resistance to wear, making it ideal for high-speed operations. Other materials such as cobalt and ceramic may also be considered based on the specific cutting requirements. Each material has its strengths and limitations, and selecting the right one depends on factors like the type of material being cut, cutting speed, and desired lifespan.

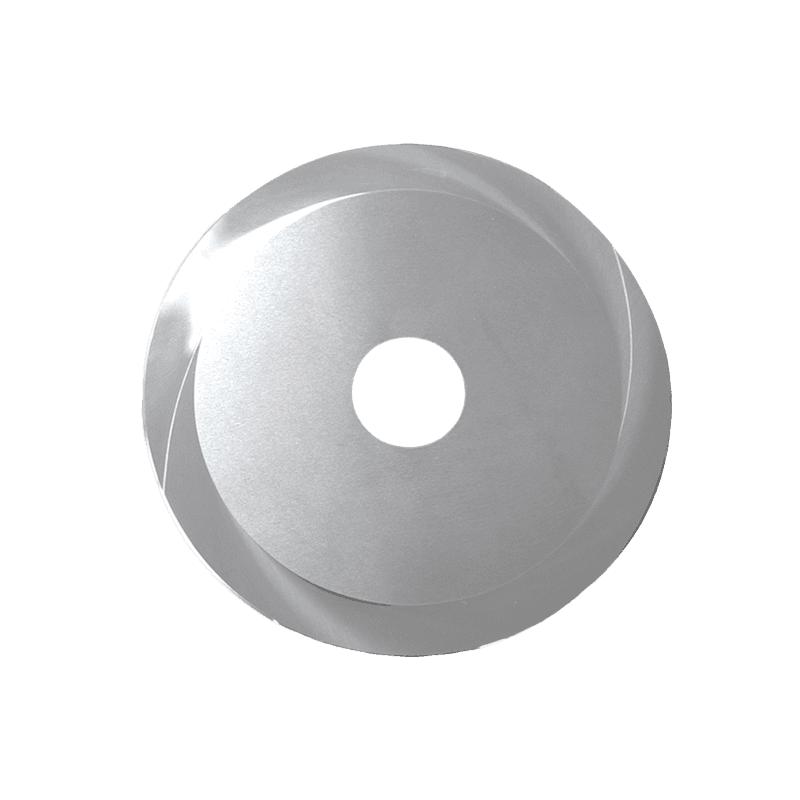

Blade design and geometry for high-speed performance

The geometry of the blade, including its thickness, curvature, and edge design, plays a significant role in its performance. In high-speed cutting, blades with fine, sharp edges and specific angles are necessary to ensure smooth cuts and prevent unnecessary friction. Additionally, the shape and size of the blade should align with the machine specifications and cutting material to optimize speed and precision. Custom blades can be engineered to fit these specific requirements, ensuring a higher level of accuracy and fewer operational interruptions.

Coating and treatment options for enhanced durability

Coatings and treatments can significantly extend the lifespan of custom blades and improve their performance in high-speed cutting. For example, titanium nitride coatings help reduce friction and heat buildup, allowing the blade to maintain its sharpness longer. Similarly, heat treatment processes can harden the blade, making it more resistant to wear, corrosion, and chipping. The selection of the appropriate coating or treatment process is crucial in maximizing the blade’s durability, particularly in high-speed cutting applications where the blades experience high levels of stress.

How Blade Selection Affects Operational Efficiency

The connection between blade performance and operational productivity

The performance of industrial blades directly impacts the overall productivity of a manufacturing operation. Blades that maintain sharpness and efficiency reduce the need for frequent replacements and adjustments, which in turn minimizes downtime. Moreover, high-performance blades that provide consistent cuts contribute to the efficiency of downstream processes. When the right custom blades are chosen, operators experience fewer disruptions, faster cycle times, and increased throughput, all of which are critical factors in meeting production targets.

Impact of wrong blade selection on production speed and quality

Using the wrong blade for a specific high-speed cutting application can lead to several operational problems. Poor blade selection may result in inaccurate cuts, excessive material waste, or even damage to the machinery. Furthermore, frequent blade replacements or repairs due to improper blade choices can cause costly downtime and disrupt the production process. A wrong blade choice can also impact the overall quality of the end product, leading to inconsistencies that affect customer satisfaction.

Reducing Downtime with the Right Blade Choice

How choosing the right custom blades minimizes machine downtime

Downtime is one of the most costly and disruptive factors in industrial operations. By selecting the right custom blades, downtime can be significantly reduced. Custom blades, designed to handle the specific demands of high-speed cutting, typically last longer and perform more reliably than standard blades. This reliability reduces the frequency of blade changes and the need for unexpected repairs, thus improving machine uptime and keeping operations running smoothly.

The relationship between blade longevity and maintenance cycles

Long-lasting custom blades contribute to extended maintenance cycles, saving both time and money. When blades are properly designed to withstand the wear and tear of high-speed cutting, they require less frequent sharpening or replacement. This, in turn, reduces the overall maintenance costs for the equipment, as well as the need for unplanned downtime. Blade longevity is a key consideration when choosing the right custom blade, as it can have a direct impact on the maintenance schedule and cost efficiency of an operation.

The Impact of Precision in High-Speed Cutting

How precision blades contribute to more accurate cuts

In high-speed cutting, precision is paramount. Custom blades designed for precision cutting ensure that each cut is consistent and accurate, which is essential for high-quality production. High-precision blades minimize the risk of errors and rework, allowing for smooth operations and better product consistency. The ability to achieve exact cuts also reduces the waste of materials, which contributes to higher efficiency and lower costs.

The importance of tight tolerances for optimal cutting performance

Tight tolerances are critical in high-speed cutting operations. Blades with precise tolerances ensure that every cut meets exact specifications, which is particularly important in industries where product uniformity is vital. Custom blades can be engineered to meet these tight tolerances, delivering superior cutting performance and minimizing variation in the final product. Achieving tight tolerances reduces scrap rates and improves the overall quality of production.

Cost Efficiency through Proper Blade Selection

Long-term savings through choosing the right custom blades

Although custom blades may involve higher upfront costs, they offer significant long-term savings. The durability and efficiency of custom blades lead to fewer replacements, less maintenance, and reduced downtime. Over time, these savings offset the initial investment, making custom blades a cost-effective solution for high-speed cutting applications. By choosing the right blades, companies can improve their bottom line while maintaining high production standards.

Minimizing waste and rework by selecting the optimal blade

Selecting the right custom blade not only reduces downtime but also minimizes waste. Inaccurate cuts often lead to material waste, defects, and rework. With the correct blade, high-quality cuts are ensured, reducing the likelihood of wasted materials and the need for corrective actions. This results in both direct and indirect cost savings, improving the overall efficiency of the production process.

The Role of Blade Maintenance in Maintaining Performance

Best practices for maintaining custom blades for high-speed cutting

Proper maintenance is essential to ensuring the continued performance of custom industrial blades. Regular inspection, cleaning, and sharpening are key practices to keep blades functioning at their best. Additionally, ensuring that blades are properly stored and handled helps to preserve their integrity. Following the manufacturer’s recommended maintenance schedule is crucial for extending the lifespan of custom blades and maintaining consistent cutting quality.

The influence of regular maintenance on blade lifespan and cutting consistency

Routine maintenance directly affects the longevity and effectiveness of custom blades. Well-maintained blades stay sharper for longer, which translates to better cutting performance and fewer operational disruptions. Regular maintenance also ensures that blades are performing at their optimal capacity, minimizing the risk of errors or subpar cuts. Ultimately, the more consistent the blade’s performance, the less downtime and waste there will be in the cutting process.

Case Studies: Real-World Examples of Success

Examples of companies that improved operations by choosing the right custom blades

Several companies across industries have significantly benefited from choosing the right custom blades for high-speed cutting. For example, a packaging company improved its production speed by selecting blades specifically designed for cutting corrugated materials. As a result, they saw a reduction in blade replacements, an increase in cut quality, and a boost in overall productivity. Another manufacturer in the automotive industry selected custom blades for cutting metal components, leading to a decrease in operational downtime and higher throughput.

How correct blade selection led to reduced downtime and higher throughput

In another case, a paper processing facility implemented custom blades designed for high-speed cutting of thick paper rolls. The tailored blades were able to withstand the high friction and heat generated during cutting, which reduced the need for maintenance and allowed the machines to run at full capacity for longer periods. This led to increased throughput and a noticeable reduction in downtime, proving that choosing the right blades is key to operational success.

Conclusion

Choosing the right custom industrial blades for high-speed cutting can have a profound impact on operational efficiency, precision, and downtime reduction. By understanding the critical factors in blade selection, such as material, design, and coating options, industries can significantly improve productivity while maintaining high-quality results. Custom blades not only ensure better performance but also deliver long-term savings by reducing waste, minimizing downtime, and enhancing blade longevity. By investing in the right tools for high-speed cutting, businesses can optimize their operations and stay competitive in an increasingly fast-paced industrial landscape.