Understanding High-Performance Cutter Blades

High-performance cutter blades are engineered to deliver exceptional cutting capabilities that surpass those of standard blades. Constructed from advanced materials, such as high-speed steel, carbide, and ceramic composites, these blades offer increased hardness and resilience, facilitating longer lifespans and reduced maintenance needs. The choice of materials plays a critical role in determining the performance characteristics of the blades; for instance, carbide blades are particularly effective for cutting through tough materials, while high-speed steel blades are valued for their high durability and resistance to deformation.

The design features inherent in high-performance cutter blades further enhance their operational efficiency. These designs often incorporate specialized geometries, such as optimized angles and variable tooth shapes, that minimize friction and maximize cutting speeds. Furthermore, many blades are treated with advanced coatings, such as titanium nitride or diamond-like carbon, to reduce wear and enhance the cutting surfaces’ heat resistance. Such technologies not only improve blade longevity but also optimize overall cutting precision and efficiency.

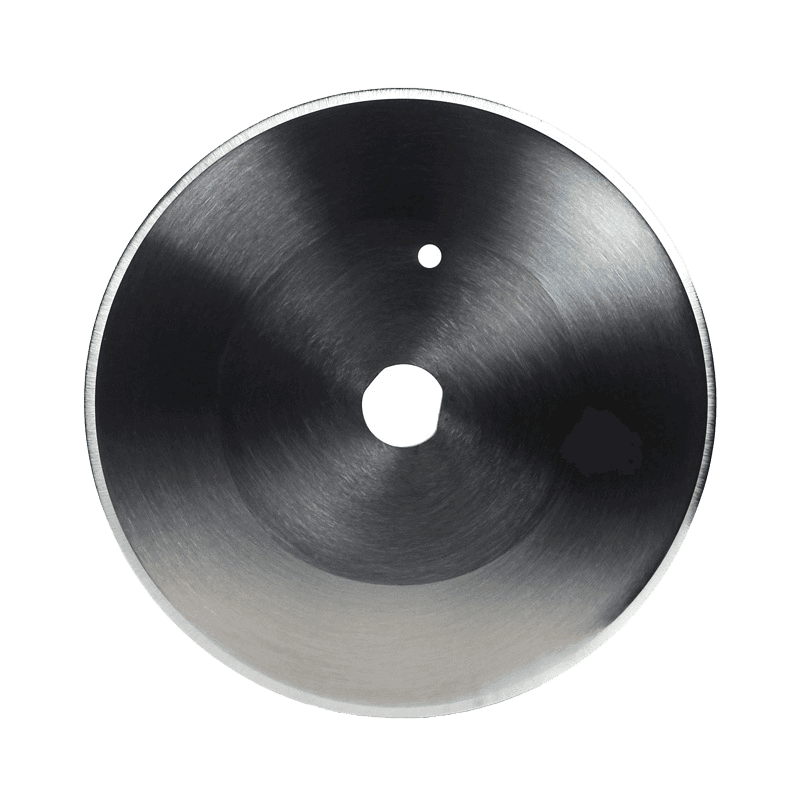

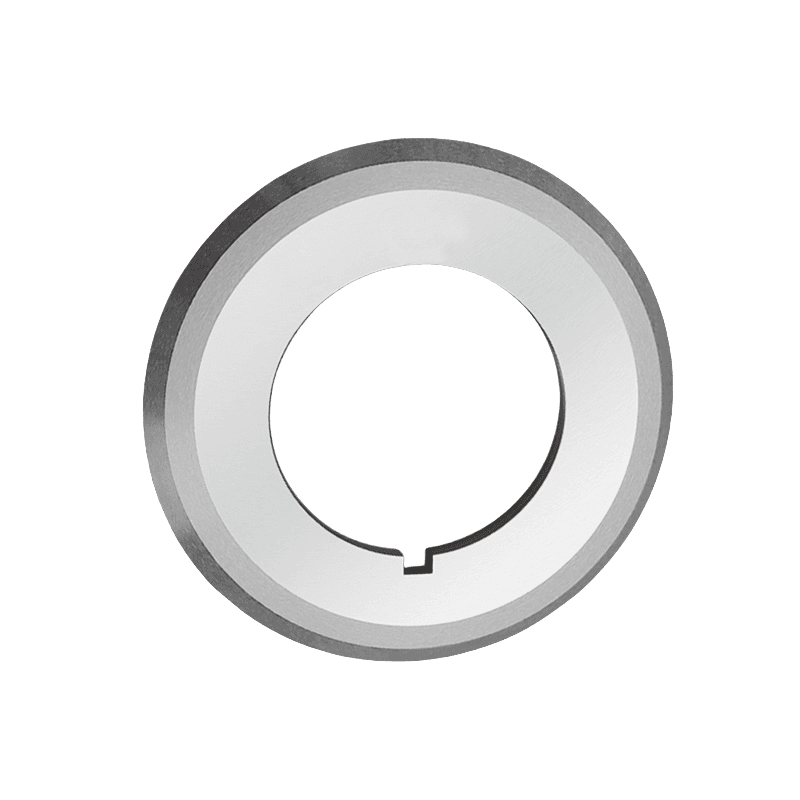

Different types of high-performance blades are available to accommodate the various needs of industrial applications. From circular saw blades to router bits and milling cutters, each type is tailored to specific machinery and material requirements. It is critical for operators to select the appropriate high-performance cutter blades based on their intended use, as the right choice can significantly enhance cutting precision, speed, and overall productivity. Users can experience marked advantages by understanding the distinctions between standard and high-performance blades, ensuring that their cutting operations achieve the best possible outcomes.

The Benefits of Using High-Performance Cutter Blades

High-performance cutter blades offer numerous advantages that make them superior choices for both industrial and commercial applications. One of the foremost benefits is increased productivity. These blades are designed to cut through various materials with greater speed and efficiency, significantly reducing cutting times. This means that businesses can accomplish more in less time, leading to enhanced overall output and workflow efficiency.

In addition to faster cutting times, high-performance cutter blades also contribute to reduced downtime. Traditional blades may dull quickly, necessitating frequent replacements or sharpening, which interrupts work processes. In contrast, high-performance blades are engineered for durability, featuring materials that resist wear and tear. As a result, they have a longer life span, allowing operations to run smoothly without the disruptions that come from frequent blade changes.

The quality of cuts produced by these advanced blades is another critical advantage. With high-performance cutter blades, users can expect cleaner and more precise cuts. This precision translates into less material waste and lower production costs, making them a viable investment for any business. Furthermore, the superior cutting performance ensures that the finished products meet high-quality standards, which is essential in maintaining customer satisfaction and brand reputation.

Cost-effectiveness is also a significant factor to consider. Although high-performance cutter blades may come with a higher initial investment, the savings accrued through reduced replacement frequency, minimized downtime, and decreased waste can surpass the costs over time. Alongside financial benefits, the reliability and consistency of these blades improve workplace safety. Their performance minimizes the chances of accidents related to blade failures or dullness, creating a safer environment for all workers.

Choosing the Right Blade for Your Machinery

Selecting the appropriate high-performance cutter blades for your machinery is crucial for achieving optimal cutting efficiency and ensuring the longevity of both the blades and the equipment. One of the primary considerations is the blade size, which must fit the specifications of your machinery. It is essential to consult the manufacturer’s guidelines or user manuals to determine the correct dimensions required for safe and effective operation.

Another important factor is the compatibility of the cutter blades with your specific machinery type. Different machines may require different designs or configurations of blades, which can influence performance. It is advisable to examine the requirements of your cutting machine and align them with the specifications of the high-performance cutter blades you are considering.

The type of material being cut also plays a significant role in selecting the right blade. Various materials, whether they are metal, wood, plastic, or composite, necessitate distinct blade constructions and edge geometries. For instance, blades designed for metal cutting often feature a different tooth design compared to those used for cutting softer materials like wood. Furthermore, understanding the specific cutting conditions—such as the speed, feed rate, and temperature—can profoundly impact blade performance and durability.

When in doubt, consulting with manufacturers or industry experts can provide invaluable insights into the best match between blade and machinery. These professionals can guide you through the selection process, ensuring that you choose high-performance cutter blades tailored to your needs. By taking into account the right size, compatibility, material type, and cutting conditions, you can enhance your operational efficiency and achieve superior cutting results.

Where to Buy High-Performance Cutter Blades

Finding the right source for high-performance cutter blades is crucial for ensuring quality and reliability in your projects. A variety of purchasing options are available, catering to different preferences and needs. One of the primary avenues for procurement is specialized tool suppliers. These suppliers typically offer a wide range of cutter blades tailored to specific applications, providing expertise and guidance alongside their products. This option is particularly beneficial for those seeking detailed information about performance characteristics and suitable blade types.

Online marketplaces have also gained popularity for purchasing high-performance cutter blades, offering convenience and a broader selection at competitive prices. Websites such as Amazon, eBay, and dedicated hardware retailers allow customers to compare various brands and models swiftly. However, it is essential to exercise caution when ordering online. Reading customer reviews and evaluating seller ratings can significantly influence the quality of the purchase and ensure you receive reliable products.

For those who prefer a more direct approach, purchasing from manufacturers is another viable option. Many manufacturers operate their own online stores or have partnerships with distributors that simplify the purchasing process. This method not only guarantees direct access to the latest high-performance cutter blades but often assures customer support for technical inquiries and product details. When deciding where to buy, it is imperative to choose reputable sources to avoid substandard products that can compromise performance and safety.

Some renowned brands in the cutter blade industry include Bosch, Milwaukee, and Dewalt, known for their commitment to quality and innovation. However, regardless of the chosen brand, conducting thorough research before a purchase is critical. By focusing on established suppliers, understanding product specifications, and relying on customer feedback, you can confidently select high-performance cutter blades that meet your project requirements.