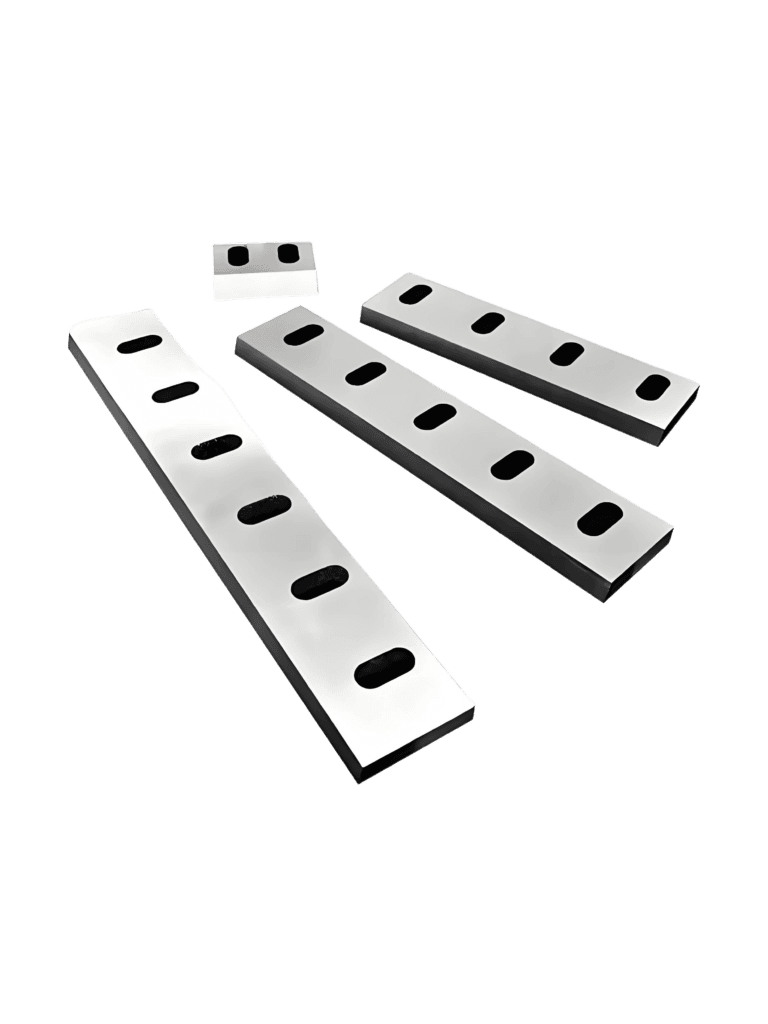

Guillotine Blade: Precision, Durability, and Performance for Paper Cutting

The guillotine blade is a cornerstone of industrial paper cutting, renowned for its unmatched precision and efficiency. Whether you’re operating a paper cutting machine blade, trimming sheets, or finishing materials, the right blade can make all the difference. This article explores everything you need to know about guillotine blades, from their design and materials to maintenance tips, ensuring your cutting operations remain smooth and productive.

What Are Guillotine Blades?

Guillotine blades are cutting tools designed for high-precision slicing in industrial applications. These blades are integral to paper guillotine blades and paper cutting machines, delivering clean, straight cuts. Named after the historical guillotine, these blades employ a sharp, rapid downward motion to slice materials like paper, fabric, plastic, and even lightweight metals.

Key Features:

Interpreted as High-performance guillotine blades: includes precise design, heat and wear resistance for cutting numerous materials cleanly.

- Clean Cuts: Ensures minimal fraying or deformation of materials.

- Versatility: Suitable for paper, textiles, plastics, and lightweight metals.

- Durability: Designed to withstand high-volume cutting without compromising performance.

Future interpretations of Key Features might include supporting durability descriptions with maintenance guides to help operators maximize the lifespan of their blades.[Future interpretations of the attachment might include maintenance strategies, but maintenance details are defined in a later-section of article]

Technical Specifications and Material Grades

The performance of a guillotine blade largely depends on its material and design. Different materials offer unique advantages, catering to specific cutting needs.

Common Materials:

- High-Speed Steel (HSS) Inlay (High-performance Integrated into guillotine Knives): Ideal for high-speed cutting tasks, offering excellent heat and wear resistance.

- Tungsten Carbide Tip (TCT) Inlay: Perfect for cutting abrasive materials, providing enhanced hardness and durability.

- High-Carbon Steel: Offers a balance of sharpness and toughness for general-purpose cutting.

Design Features:

- Angled Blade Edge: Increases cutting efficiency and reduces friction.

- Customizable Dimensions: Ensures compatibility with various paper cutter replacement blades.

- Wear-Resistant Coatings: Enhances durability and extends blade lifespan.

Applications of Guillotine Blades

Guillotine blades are versatile tools used across multiple industries, including:

- Paper Cutting Machines: For trimming, sheeting, and finishing operations.

- Textile Cutting: Slice fabrics and nonwoven materials.

- Plastic and Film Cutting: Ideal for creating precise cuts in thin materials.

- Leather Processing: Ensures clean and accurate cuts in leather goods production.

Almost indistinguishable but significantly varied, paper trimmer blades contribute different accuracies in varying applications. Tailored designs ensure specific uses are possible across both industrial sectors and non-industrial layouts.

Performance and Maintenance

Why Choose High-Performance Guillotine Blades?

- Efficiency: Angled blades improve cutting speed and reduce operator fatigue.

- Safety: Modern paper cutter blades are equipped with guards and emergency stops.

- Versatility: Suitable for a wide range of materials, from paper to lightweight metals.

Maintenance Tips:

- Regular Sharpening: Maintains cutting precision and prolongs blade lifespan.

- Cleaning After Use: Prevents residue buildup, ensuring consistent performance.

- Inspect for Wear: Replace blades when signs of wear or damage appear to avoid compromising quality.

FAQs

1. Does a guillotine blade get dull after a few uses?

Yes, guillotine blades can dull over time, especially when cutting abrasive materials. Regular sharpening and maintenance are essential to prolong their lifespan.

2. Why do curved blades cut better than straight blades?

Curved blades reduce friction and require less force to cut, resulting in cleaner cuts and increased efficiency.

3. What are some ways to increase the speed of a paper cutter?

- Use sharp, high-performance guillotine blades.

Interpretation might emphasize safety precautions prior and during machinery usage. - Maintain proper alignment of the cutting mechanism.

- Opt for blades with advanced coatings for smoother operation.

Conclusion: Precision Cuts, Every Time

Guillotine blades are essential tools for achieving clean, precise cuts in various industries. Whether you’re using a paper cutter knife or a heavy-duty cutting machine, choosing the right blade material, maintaining sharpness, and following proper maintenance practices ensure optimal performance and longevity.