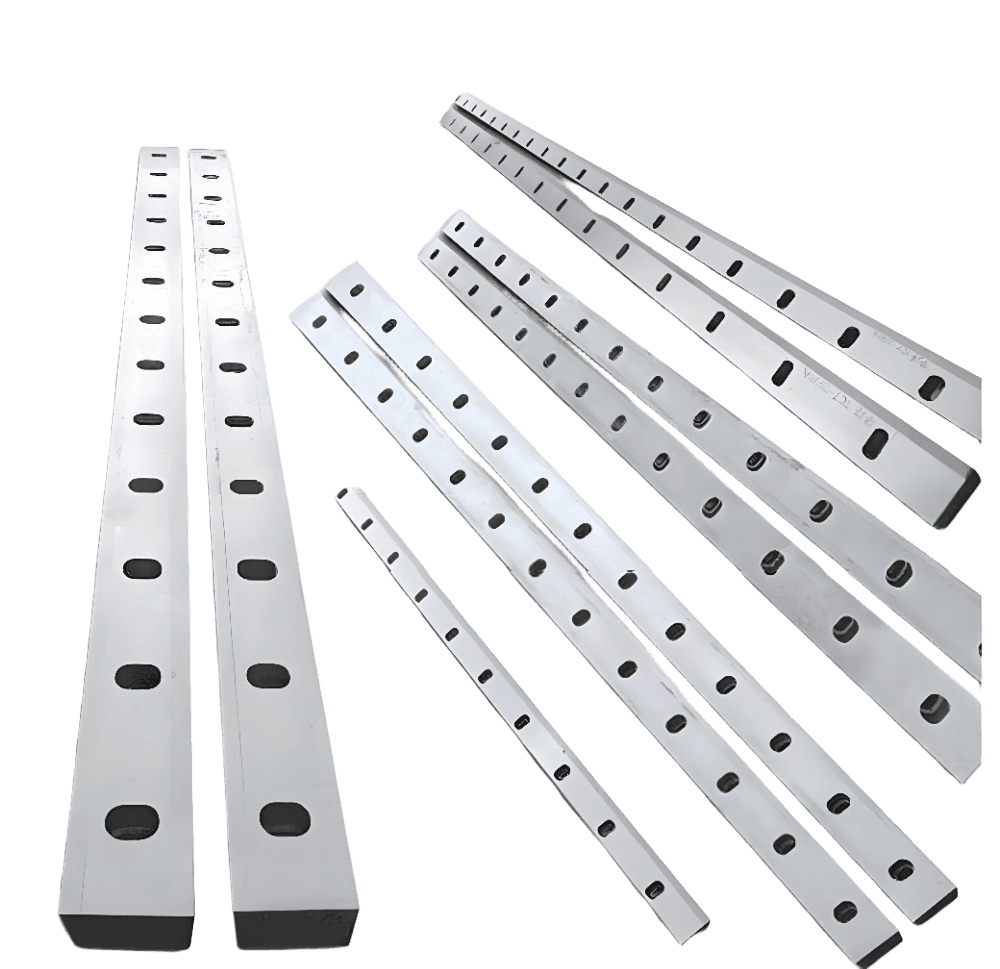

In the demanding world of industrial cutting tools, the straight track cutting knife represents the pinnacle of precision, efficiency, and consistent performance. These knives, essential for achieving clean and accurate cuts across a wide range of materials, are integral to numerous manufacturing processes. As leading cutting tools manufacturers with over 25 years of expertise, we deliver exceptional solutions for diverse industrial applications, empowering businesses to optimize their production processes and achieve superior results. Understanding the nuances of straight track cutting knife design, materials, and applications is critical for selecting the optimal tool for your specific needs. Whether you’re processing paper, fabricating metal, or manufacturing textiles, choosing the right cutting knife can significantly impact your productivity, quality, and overall profitability. The consistent demand has allowed many cutting tools factory to exist.

Technical Specifications: Unveiling the Core Attributes

To fully appreciate the capabilities of a straight track cutting knife, it’s essential to delve into its technical specifications. These specifications define the knife’s performance characteristics, material compatibility, and overall suitability for various industrial applications.

Key Features: The Cornerstones of Performance

- High-Precision Cutting Edge: The cutting edge is the heart of any cutting knife, and a straight track knife is no exception. The geometry, sharpness, and material of the cutting edge directly influence the quality of the cut, the force required, and the lifespan of the blade. High-precision cutting edges are meticulously engineered to minimize burrs, prevent material deformation, and ensure clean, consistent cuts every time. Factors such as edge angle, surface finish, and the presence of specialized coatings all contribute to the overall performance of the cutting edge.

- Customizable Dimensions: In the world of industrial cutting, one size rarely fits all. Different applications demand knives with specific dimensions to accommodate varying material thicknesses, cutting widths, and machine configurations. Leading cutting tools manufacturers offer a wide range of customizable dimensions, allowing you to tailor the knife to your exact needs. This flexibility ensures optimal cutting performance, minimizes waste, and maximizes efficiency.

- Advanced Alloy Steel Construction: The material used to construct a straight track cutting knife profoundly impacts its durability, wear resistance, and ability to withstand the stresses of industrial cutting. Advanced alloy steels, carefully selected for their unique properties, provide the ideal balance of hardness, toughness, and resistance to abrasion. These high-performance materials ensure that the knife maintains its sharpness and structural integrity, even under demanding cutting conditions.

- Multiple Material Compatibility: A versatile straight track cutting knife should be capable of processing a wide range of materials, from paper and plastics to metals and textiles. The knife’s design, material, and edge treatment should be carefully chosen to ensure compatibility with the intended materials, preventing premature wear, minimizing material deformation, and ensuring clean, accurate cuts across the board.

- Wear-Resistant Coatings: In demanding industrial environments, cutting knives are subjected to significant wear and abrasion. To extend the lifespan of the knife and maintain its cutting performance, wear-resistant coatings are often applied to the blade surface. These coatings, typically composed of hard materials such as titanium nitride (TiN) or chromium nitride (CrN), reduce friction, minimize material adhesion, and protect the blade from corrosion and wear.

Technical Specifications Table: A Detailed Overview

| Specification | Description |

|---|---|

| Material | High-speed steel (HSS), Tungsten carbide, Alloy steel |

| Hardness | 58-65 HRC (HSS), 70-90 HRA (Tungsten carbide) |

| Edge Angle | 20-40 degrees (depending on application) |

| Surface Finish | Ra 0.2-0.8 µm (micro-meters) |

| Coating Options | TiN, CrN, DLC (Diamond-like carbon) |

| Dimensional Tolerance | +/- 0.01 mm |

| Length | Customizable (up to several meters) |

| Width | Customizable (typically 10-100 mm) |

| Thickness | Customizable (typically 1-50 mm) |

Manufacturing Excellence: The Foundation of Quality

The quality of a straight track cutting knife is inextricably linked to the manufacturing processes employed in its creation. Leading cutting tools factory invest heavily in advanced manufacturing technologies and rigorous quality control procedures to ensure that their knives meet the highest standards of performance and reliability.

Key Manufacturing Processes:

- Advanced CNC Machining: Computer Numerical Control (CNC) machining is a cornerstone of modern cutting knife manufacturing. CNC machines utilize computer-controlled precision to shape the blade, create the cutting edge, and ensure dimensional accuracy. This automated process minimizes human error, maximizes efficiency, and allows for the creation of complex blade geometries with exceptional precision.

- Strict Quality Control Processes: From raw material inspection to final product testing, quality control is paramount throughout the manufacturing process. Rigorous quality control procedures ensure that each knife meets exacting specifications for dimensions, hardness, surface finish, and cutting performance. Statistical process control (SPC) techniques are often employed to monitor manufacturing processes and identify potential deviations from established standards.

- Comprehensive Material Testing: The properties of the materials used in a straight track cutting knife directly influence its performance and lifespan. Comprehensive material testing is conducted to verify that the materials meet the required specifications for hardness, toughness, tensile strength, and resistance to corrosion. This testing may involve techniques such as hardness testing, tensile testing, and metallographic analysis.

- Precision Engineering Techniques: The creation of a high-performance straight track cutting knife requires a deep understanding of engineering principles and meticulous attention to detail. Precision engineering techniques, such as finite element analysis (FEA) and computer-aided design (CAD), are employed to optimize blade geometry, minimize stress concentrations, and ensure structural integrity.

Industry Applications: A Versatile Tool for Diverse Sectors

The straight track cutting knife finds applications in a wide range of industries, each benefiting from its precision, efficiency, and versatility.

- Paper Processing: In the paper processing industry, straight track cutting knives are used for slitting, sheeting, and trimming paper rolls with exceptional accuracy. These knives are essential for producing high-quality paper products with clean, consistent edges.

- Metal Fabrication: Straight track cutting knives are employed in metal fabrication for shearing, slitting, and blanking metal sheets and plates. These knives must be capable of withstanding the high forces and abrasive conditions associated with metal cutting.

- Packaging: In the packaging industry, straight track cutting knives are used to cut and score cardboard, paperboard, and other packaging materials. Precise cutting is essential for creating accurately sized and shaped packaging containers.

- Textile Manufacturing: Straight track cutting knives are utilized in textile manufacturing for cutting fabrics, textiles, and nonwoven materials. These knives must be sharp and precise to prevent fraying and ensure clean cuts.

- Electronics Production: In the electronics industry, straight track cutting knives are used for cutting and trimming printed circuit boards (PCBs) and other electronic components. Precision and accuracy are essential to avoid damaging sensitive electronic components.

Customization Options: Tailoring the Knife to Your Needs

Recognizing that every industrial application has unique requirements, leading cutting tools manufacturers offer comprehensive customization options for straight track cutting knives. This allows you to tailor the knife to your specific needs, optimizing its performance and maximizing its efficiency.

Key Customization Options:

- Custom Blade Dimensions: As mentioned earlier, customizing the blade dimensions is crucial for achieving optimal cutting performance. You can specify the exact length, width, and thickness of the knife to match your machine configuration and material thickness.

- Specialized Material Selections: Depending on the material being cut and the cutting conditions, you may choose from a range of specialized materials, such as high-speed steel, tungsten carbide, or a specific alloy steel with enhanced wear resistance or toughness.

- Unique Edge Treatments: The edge treatment can be tailored to optimize cutting performance for specific materials. Options include honed edges for clean cuts, serrated edges for aggressive cutting, and beveled edges for scoring or creasing.

- Application-Specific Designs: For highly specialized applications, you can work with experienced engineers to design a custom straight track cutting knife that meets your exact requirements. This may involve modifying the blade geometry, adding specialized features, or incorporating unique materials and coatings.

Frequently Asked Questions: Addressing Your Concerns

To further enhance your understanding of straight track cutting knives, we have compiled a list of frequently asked questions:

Q: How do I select the right cutting knife for my specific industrial application?

A: Selecting the right cutting knife requires careful consideration of several factors:

- Material Hardness: The hardness of the material being cut will influence the choice of blade material and edge treatment.

- Cutting Thickness: The thickness of the material will determine the required blade thickness and cutting force.

- Specific Industrial Application: The specific application will dictate the required blade geometry, dimensions, and material compatibility.

- Required Precision Level: The desired level of precision will influence the choice of manufacturing processes and quality control procedures.

Consulting with experienced cutting tools manufacturers can provide valuable guidance in selecting the optimal knife for your needs.

Q: What factors make MAIDECAL’s cutting tools unique and superior to those offered by other manufacturers?

A: With over 28 years of industrial experience, a commitment to innovation, and a focus on customer satisfaction, we are a trusted partner for businesses worldwide. Key differentiators include:

- Global Supply Capabilities: With worldwide supply, we can meet your needs wherever you are.

- Over 2,000 Blade Inventory: We have over 2,000 blades in stock, ready for shipment to you.

- Rapid Delivery Guarantees: We guarantee the fastest delivery to keep your machines running smoothly .

The Cutting Edge of Innovation

As technology continues to evolve, so too will the design and manufacturing of straight track cutting knives. Future trends may include the incorporation of smart sensors to monitor blade wear, the development of new high-performance materials, and the use of additive manufacturing (3D printing) to create complex blade geometries.

Conclusion: Partnering for Success

The straight track cutting knife is an indispensable tool for a wide range of industrial applications. By understanding the technical specifications, manufacturing processes, and customization options available, you can select the optimal knife for your specific needs and optimize your production processes. Partnering with experienced cutting tools manufacturers ensures access to high-quality knives, expert technical support, and customized solutions that drive success.