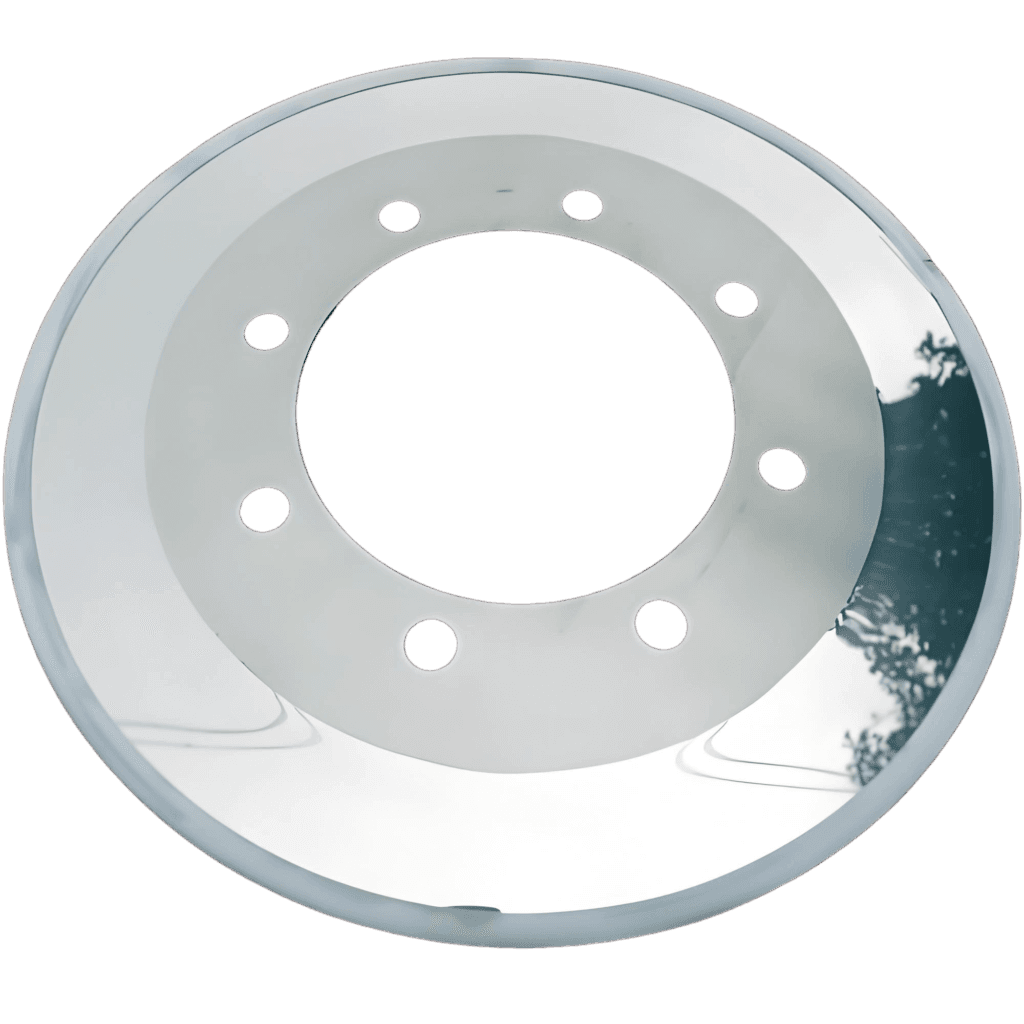

Corrugator Blade Specifications

| Specification | Value |

|---|---|

| Outer Diameter (OD) | 291mm |

| Thickness | 1mm |

| Edge Angle | 20° |

| Material | 100% Virgin Tungsten Carbide |

| Compatibility | Fosper Series Machines |

| Cutting Edge | Razor-Sharp, Non-Stick |

Key Features & Benefits

✅ Superior Tungsten Carbide Material

Our corrugator blade is manufactured from premium virgin tungsten carbide, offering exceptional hardness and wear resistance. Compared to standard steel blades, this ensures longer tool life, reducing maintenance and replacement costs.

✅ Precision Cutting for Clean Edges

The razor-sharp 20° cutting angle enables smooth, accurate cuts with minimal roughness, ensuring that corrugated boards retain their integrity and finish. This reduces edge burrs and dust, enhancing overall production quality.

✅ Non-Stick Cutting for High-Speed Performance

With a low-friction, non-stick cutting edge, our blade significantly reduces heat buildup and friction, preventing material adhesion. This improves cutting efficiency and extends blade life.

✅ Optimized for Fosper Series Machines

Designed to seamlessly fit Fosper series corrugating machines, our blade ensures quick installation and minimal downtime. This allows for continuous high-speed operation, maximizing production efficiency.

Why Choose Our Corrugator Blade?

📌 Increased Productivity – Longer-lasting blades reduce replacement frequency. 📌 Cost Efficiency – Lower operational costs with extended durability. 📌 High-Quality Cutting – Precise and burr-free edges enhance product quality. 📌 Eco-Friendly Production – Reduced material waste contributes to sustainability.

By investing in our high-performance tungsten carbide corrugator blades, manufacturers can achieve greater cutting precision, efficiency, and cost savings.

Order Your Corrugator Blades Today!

Need high-quality tungsten carbide blades for your corrugated packaging operations? Contact us now to request a quote and optimize your cutting performance.

📌 Request a Quote | 📌 Learn More