Introduction

In the manufacturing industry, the precision, durability, and efficiency of cutting tools are paramount. Circular slitting knives, essential for cutting materials such as paper, film, and textiles, play a crucial role in determining the quality and efficiency of production processes. This article explores the latest trends and innovations in circular slitting knives, focusing on their impact on manufacturing precision, durability, and efficiency.

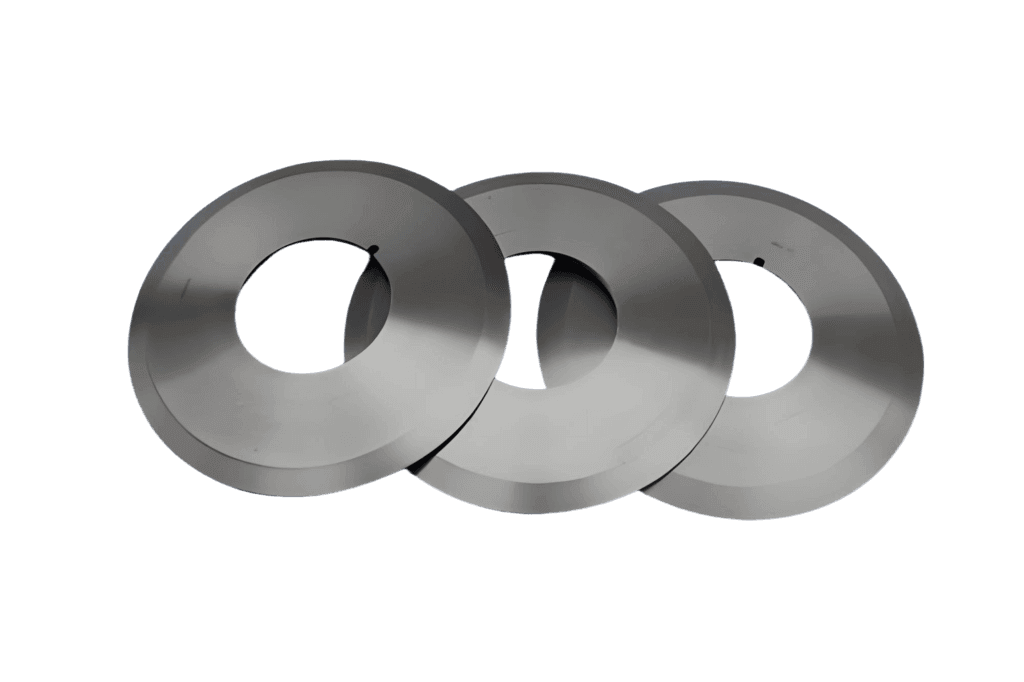

Understanding Circular Slitting Knives

Circular slitting knives are rotary cutting tools designed to slice through various materials with high precision. They are commonly used in industries like paper, film, and textile manufacturing. The primary types include flat circular knives, serrated circular knives, high-speed steel knives, and alloy knives, each tailored for specific cutting requirements.

Enhancing Precision in Manufacturing

Achieving precise cuts is vital for product quality and consistency. Circular slitting knives contribute to this by providing clean, accurate cuts that meet stringent industry standards. The sharpness and design of the knives ensure minimal material waste and uniformity in the final product.

Improving Durability and Longevity

The durability of slitting knives directly affects production efficiency and costs. Modern knives are often made from high-quality materials and coated with substances like titanium nitride (TiN) or titanium carbonitride (TiCN) to enhance wear resistance. These advancements result in longer tool life, reduced frequency of replacements, and lower maintenance costs for manufacturers.

Boosting Efficiency in Production Processes

Advanced circular slitting knives enable faster cutting speeds without compromising quality. This increase in cutting efficiency leads to higher production rates, reduced downtime, and significant cost savings. Manufacturers benefit from streamlined operations and improved profitability.

5 Secrets to Cut with Blade Efficiently and Safely

Trends and Innovations in Circular Slitting Knives

The industry is witnessing several innovations aimed at enhancing slitting knife performance:

- Advanced Coatings: The application of coatings like TiN and TiCN improves hardness and wear resistance, extending tool life.

- Precision Manufacturing: Advancements in manufacturing techniques allow for more precise knife edges, resulting in cleaner cuts and better product quality.

- Material Innovations: The development of new materials, such as high-speed steels and advanced alloys, offers improved performance and durability.

Addressing Industry Challenges

Manufacturers often face challenges such as tool wear, maintenance costs, and production downtime. Modern circular slitting knives address these issues by offering enhanced durability, reducing the frequency of tool changes, and minimizing maintenance requirements. These improvements lead to more efficient production processes and lower operational costs.

Conclusion

Circular slitting knives are integral to the manufacturing industry, influencing precision, durability, and efficiency. Recent advancements in materials, coatings, and manufacturing techniques have significantly enhanced their performance. By adopting these innovations, manufacturers can achieve higher product quality, increased production efficiency, and reduced operational costs. The future of circular slitting knives looks promising, with ongoing developments poised to further revolutionize manufacturing processes.