Understanding Reinforced Cutter Blades

Reinforced industrial cutter blades are specially designed cutting tools engineered to withstand harsh and demanding conditions within various industrial applications. Unlike standard cutter blades, which may struggle under extreme stress, reinforced blades incorporate advanced materials and innovative design elements that greatly enhance their performance and resilience.

The primary distinction of reinforced industrial cutter blades lies in their materials. These blades are typically manufactured from high-quality steels that have been treated through processes such as hardening and tempering. Additionally, some models incorporate carbide or ceramic coatings which increase their hardness and wear resistance. These enhancements make the blades suitable for use in applications involving abrasive or tough materials, such as metals, composites, and reinforced plastics.

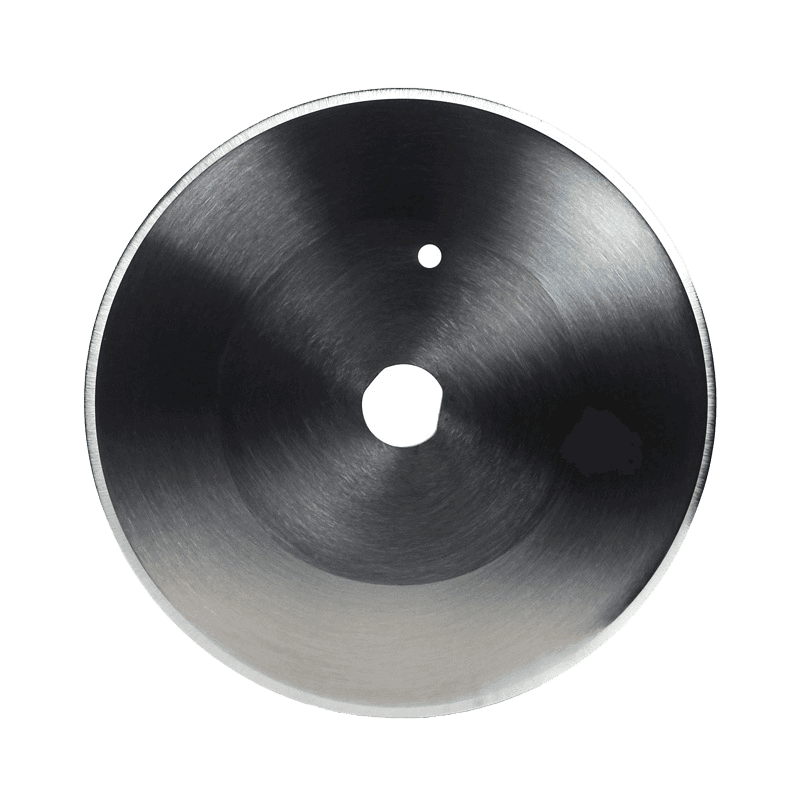

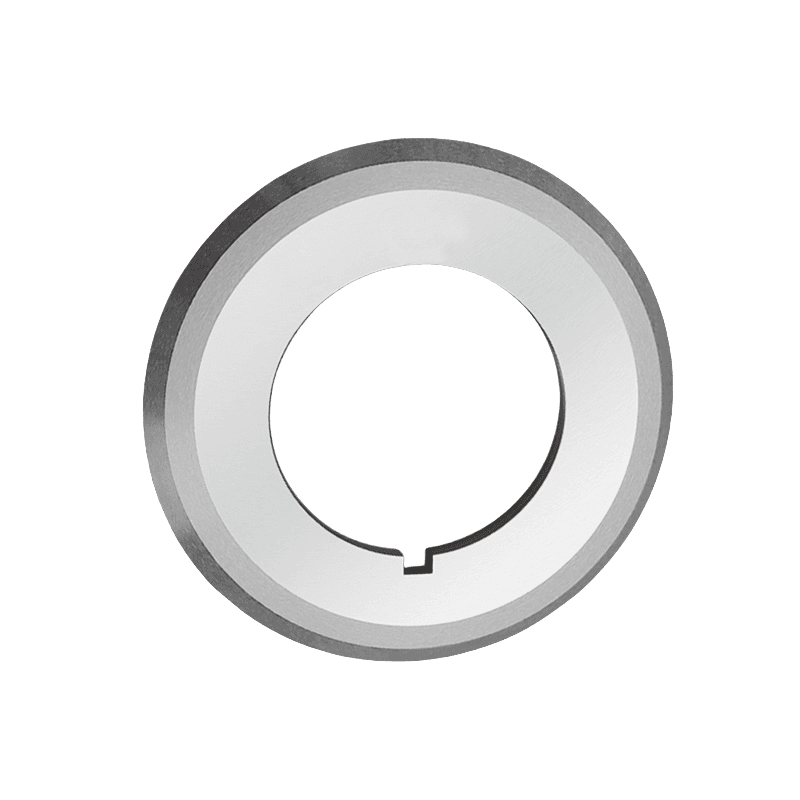

Another key feature of reinforced cutter blades is their geometry and design. The cutting edges of these blades are often sharpened to provide optimal cutting efficiency while maintaining integrity under pressure. For instance, many designs utilize a thicker body to minimize flexing, enabling the blade to operate more effectively in applications that require heavy-duty cutting. Further, some reinforced blades are designed with specialized tooth configurations that assist in preventing slippage and improving chip removal, ultimately leading to cleaner cuts and prolonged tool life.

Reinforced industrial cutter blades are indispensable in industries ranging from manufacturing to construction, where precision and durability are paramount. In environments where traditional steel blades may become dulled or fractured, the use of reinforced options can result in reduced downtime and improved productivity. Overall, the combination of high-quality materials and thoughtful design features sets reinforced cutter blades apart from their standard counterparts, exhibiting capabilities that are essential for extreme cutting conditions.

Applications of Reinforced Cutter Blades

Reinforced industrial cutter blades serve a multitude of applications across various sectors, responding adeptly to the demands posed by extreme conditions. One of the primary industries utilizing these high-performance tools is construction. In this field, reinforced blades are essential for cutting through tough materials such as concrete, steel, and asphalt. Their high durability and resistance to wear ensure that they can withstand the abrasive nature of these materials, ultimately contributing to enhanced productivity and efficiency on job sites.

Another significant application of reinforced industrial cutter blades is found in manufacturing. The ability to maintain sharp edges while enduring high-speed operations is a hallmark of these blades, making them indispensable in factories where precision cutting is crucial. Industries producing automotive components or machinery rely on these blades for their longevity and effectiveness in high-pressure environments, where traditional blades may falter. For instance, metal stamping operations frequently employ reinforced blades to achieve clean cuts and extend the life of their equipment.

Metalworking is yet another arena where reinforced cutter blades demonstrate their capabilities. Tasks such as machining, drilling, and shaping are often executed under conditions that could damage standard blades. Here, the enhanced rigidity and toughness of reinforced blades make them ideal candidates for cutting various metals, including aluminum and stainless steel. The increased resistance to deformation and fracture plays a critical role in maintaining operational safety and reducing downtime due to tool replacement.

Moreover, suppliers who provide reinforced industrial cutter blades often highlight their adaptability to different cutting applications, which allows businesses to tackle specific challenges effectively. These blades not only enhance the cutting experience in extreme conditions but also offer long-term cost savings through reduced maintenance and replacement needs. Properly selecting and employing reinforced cutter blades amplifies productivity and directly contributes to operational excellence across diverse industries.

Choosing the Right Blade for Your Needs

Selecting the appropriate reinforced industrial cutter blades is a critical decision that impacts cutting efficiency and durability. Various factors must be considered to ensure that the chosen blade aligns with the specific needs of the project. One of the foremost considerations is material compatibility. Different materials, such as metals, plastics, or composites, require blades that are specifically designed to handle their unique properties. For instance, high-speed steel blades are often preferred for cutting metal, while carbide-tipped blades may be more effective for tough materials, as they maintain sharpness for extended periods.

Another important factor is the blade dimensions. Blade diameter, thickness, and the number of teeth play a significant role in cutting performance. A thicker blade tends to offer greater stability, especially in demanding conditions, while a larger diameter can enhance the cutting speed. Additionally, the number of teeth affects the quality of the cut; blades with more teeth provide finer cuts, whereas those with fewer teeth are better suited for rapid material removal. Therefore, assessing the dimensions of the reinforced cutter blade in relation to your specific cutting tasks can help optimize results.

Moreover, the nature of the cutting tasks should be thoroughly evaluated. Tasks that require intricate or detailed cuts may necessitate precision-cutting blades, whereas rough cutting applications will benefit from more robust options designed to withstand higher stress. Furthermore, consider the environment in which the blade will operate; extreme conditions, such as high temperatures or abrasive materials, necessitate blades built to endure such challenges without compromising performance.

Ultimately, a thorough understanding of these elements — material compatibility, blade dimensions, and task specifics — is essential for selecting the right reinforced industrial cutter blades for your specific needs. This knowledge not only aids in making informed decisions but also ensures optimal cutting performance in diverse industrial applications.

Where to Shop for the Best Reinforced Cutter Blades

When seeking high-quality reinforced industrial cutter blades, it is crucial to carefully consider where to make your purchase. The market is replete with suppliers and manufacturers, but not all offer products that meet the necessary standards for durability and performance in extreme conditions. To begin your search, reputable industrial tool suppliers or manufacturers specialized in cutting tools should be your first point of contact. Companies known for their commitment to quality often offer reinforced cutter blades that are built to withstand rigorous applications.

Online platforms have become increasingly popular for purchasing industrial tools, including reinforced cutter blades. Websites such as Amazon, eBay, and dedicated tool retailers often provide a broad selection of products. However, while shopping online, emphasis should be placed on a few key factors. Firstly, always check for product descriptions that detail the material specifications and the intended use of the cutter blades. Look for blades made from high-grade steel or other durable materials that ensure longevity under heavy use.

Customer reviews can serve as a vital resource when assessing the reliability of a product. Pay attention to feedback regarding the performance of reinforced industrial cutter blades, particularly in terms of their cutting efficiency and lifespan. Quality products typically garner positive reviews, indicating satisfaction among users. Additionally, check for warranties and return policies. A reliable supplier often backs their products with guarantees, reflecting their confidence in the craftsmanship of their blades.

Ultimately, investing in the right tools is essential for operational success. By choosing a trusted supplier and prioritizing quality, you can ensure that the reinforced cutter blades you select are suited to your specific needs, contributing to enhanced productivity and performance in your projects.