Introduction to Circular Industrial Blades

Circular industrial blades are specialized cutting tools characterized by their circular shape, enabling efficient slicing and shearing operations across various applications. These blades have evolved significantly over the years, tracing their origins back to rudimentary hand tools used in early manufacturing. The innovation of circular blades marked a pivotal advancement in industrial processes, allowing for enhanced precision and productivity, particularly in sectors such as woodworking, metalworking, and food processing.

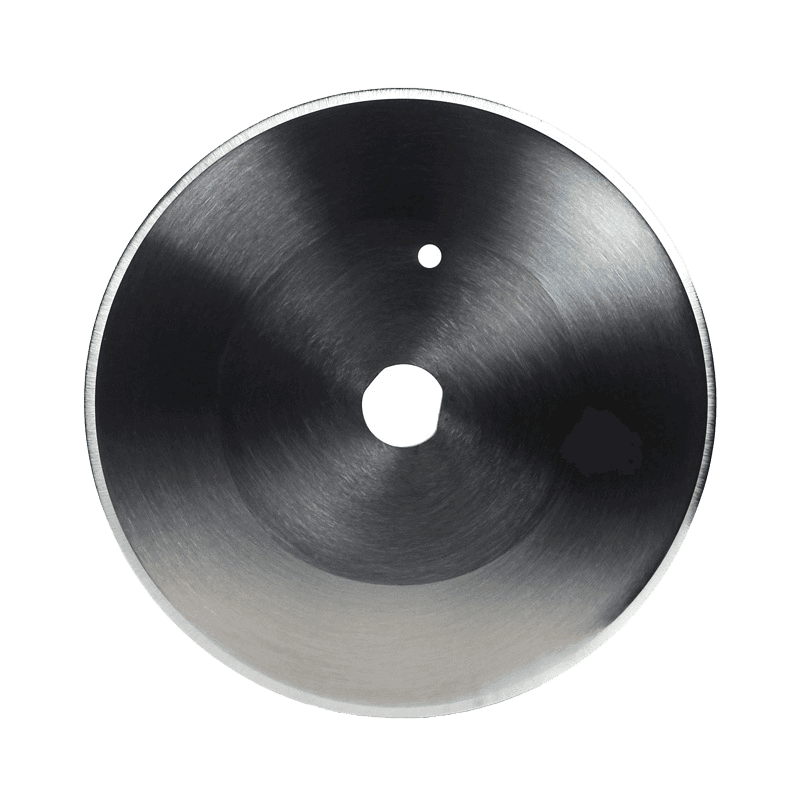

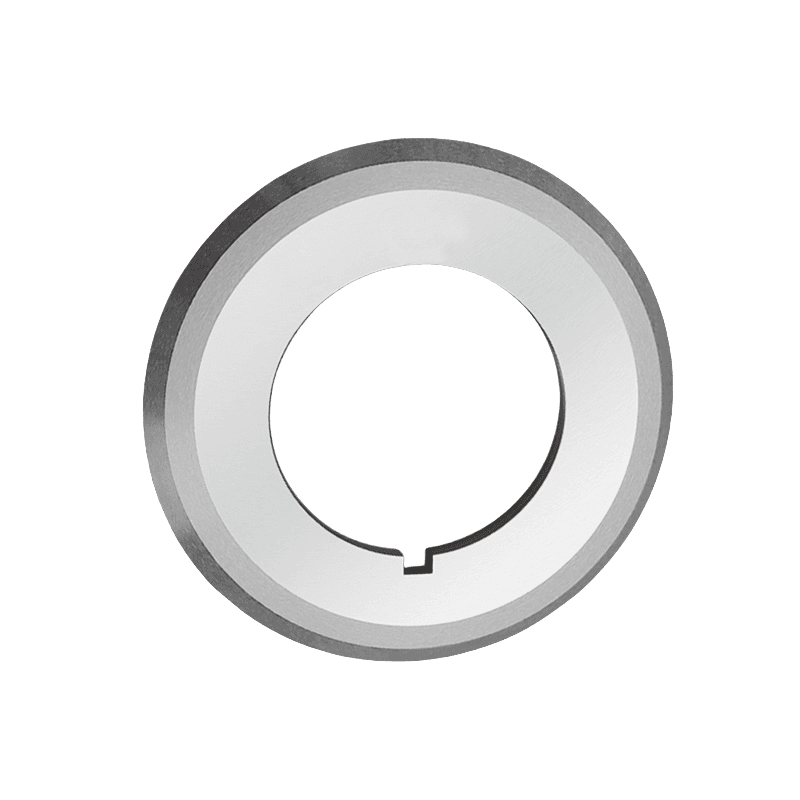

The primary design of circular blades typically involves a sharp edge with a central hole designed for mounting on a spindle or arbor. This configuration enables the blade to rotate at high speeds, facilitating seamless cutting action. Unlike traditional linear cutting tools, circular blades provide continuous motion, which results in smoother cuts and reduced material wastage. The efficiency of round industrial blades has made them indispensable in modern manufacturing, where accuracy is paramount.

The materials used in the production of circular blades play a crucial role in determining their performance and durability. Common materials include high-speed steel (HSS), carbide, and even specialized coatings that enhance wear resistance. Each type of material offers specific advantages, such as improved sharpness retention or increased resistance to heat and corrosion, making them suitable for varied applications.

Additionally, the market boasts a wide range of circular blades tailored for specific cutting tasks. From general-purpose blades used in saws to specialized designs for niche operations, each type serves a unique role in manufacturing industries. Understanding the intricacies of these blades, their functionality, and their material composition is essential for selecting the right tool for any industrial application. This foundational knowledge sets the stage for exploring the diverse applications and innovations surrounding circular industrial blades in the following sections.

Applications of Circular Industrial Blades

Circular industrial blades play a pivotal role across a multitude of industries, enhancing efficiency and precision in various cutting and manufacturing processes. One significant application of these blades is in the woodworking industry. Here, round industrial blades are employed in sawmills and woodworking shops for tasks such as cutting lumber, shaping furniture, and producing intricate wood designs. The sharpness and durability of these blades result in clean cuts that enhance the overall quality of the finished product.

In the metalworking sector, circular blades are used in metal fabrication and machining operations. Industries that engage in cutting sheets or tubes of metal rely on specialized round industrial blades designed to withstand the rigors of tough materials. For instance, high-speed steel (HSS) blades are often preferred for cutting metal due to their resistance to wear and ability to maintain sharp edges, which ultimately increases productivity and reduces downtime for tool replacement.

The packaging industry also benefits significantly from the use of circular blades. These blades are essential in processes such as slitting, trimming, and die-cutting various materials like plastic, paper, and cardboard. Efficient circular blades allow packaging manufacturers to produce consistent and quality packaging solutions, thereby improving operational efficiency and reducing waste.

In the textile industry, round blades are vital for cutting fabrics with precision. They are frequently used in various applications, including garment manufacturing and upholstery work. By utilizing appropriate circular blades, textile manufacturers can achieve precise cuts, which is essential for maintaining alignment and reducing fabric waste.

Real-world case studies illustrate that businesses utilizing the correct type of circular industrial blades experience notable improvements in efficiency and finished product quality. Understanding the specific applications and selecting appropriate blades for each task are crucial for achieving optimal results across these diverse industries.

Choosing the Right Circular Blade for Your Needs

When it comes to selecting the appropriate round industrial blades for specific applications, several factors must be considered to ensure optimal performance and longevity. Understanding these factors can play a crucial role in maximizing efficiency and safety during operations.

Firstly, the size of the circular blade is paramount. The diameter of the blade directly influences its cutting capacity and the type of materials that can be effectively processed. Different applications may require varying blade sizes, ranging from small blades suitable for intricate cuts to larger ones designed to tackle heavier materials. It is essential to align the blade size with the operational equipment and the specific requirements of the task at hand.

Secondly, material compatibility cannot be overlooked. Industrial blades are often constructed from various materials, including high-speed steel, carbide, and bi-metal composites. The choice of material depends largely on the type of material being cut. For instance, blades made from high-speed steel may be ideal for softer materials, whereas carbide-tipped blades are better suited for heavy-duty applications, offering sharpness and durability over time.

Tooth design is another vital consideration. Different applications require distinct blade tooth configurations, such as alternate top bevel (ATB) for crosscutting or flat top grind (FTG) for ripping. Understanding these designs can enhance cut quality and efficiency, ensuring that the round blades perform effectively in their intended use.

The blade coating is also significant; coatings such as TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) can reduce friction and increase wear resistance, thereby prolonging the blade’s lifespan. It is highly advisable to consult manufacturer specifications and recommendations before making a choice, as these guidelines are tailored to optimize the durability and functionality of the blades.

Moreover, proper care and maintenance are essential to extending the life of circular industrial blades. Regular sharpening and inspections can help identify any wear and tear, enabling users to address issues before they compromise performance. Following best practices for maintenance ensures that the blades continue to deliver quality results throughout their lifespan.

Future Trends in Circular Blade Technology

The technological landscape surrounding circular industrial blades is evolving rapidly, driven by the need for enhanced efficiency, sustainability, and smart manufacturing. Innovations in blade materials have become a focal point, with manufacturers increasingly opting for high-performance compounds that offer superior durability and resistance to wear. These advanced materials help extend the lifespan of round industrial blades, ultimately reducing replacements and minimizing waste.

Moreover, the design of circular blades is moving toward geometry that optimizes cutting performance. Engineers are experimenting with blade shapes and configurations that not only improve precision but also enhance the speed of the cutting process. This evolution in design directly contributes to higher operational efficiency, allowing businesses to achieve better output with lower energy consumption.

Another significant trend is the integration of smart technologies into blade performance monitoring. Sensors embedded in circular blades can provide real-time data regarding performance metrics such as temperature, vibration, and wear rates. This data is invaluable for predictive maintenance, enabling industries to proactively address issues before they lead to blade failure. Therefore, the combination of smart technologies with round industrial blades offers a forward-thinking solution for operational excellence.

Sustainability has also become a crucial priority in the circular blade industry. As businesses strive to reduce their environmental footprint, manufacturers are exploring eco-friendly practices in both production and recycling of round industrial blades. This includes using recycled materials for blade production and developing new methods for recycling worn blades, thus closing the loop in the lifecycle of industrial equipment.

Looking ahead, companies that embrace these trends will be better positioned to adapt to an ever-evolving market landscape. By anticipating technological advancements and integrating sustainable practices, businesses can not only improve their efficiency and productivity but also contribute positively to environmental conservation efforts.